2 min read

Sustainable Innovations in Packaging: December Round-Up

ResourceWise

:

Jan 13, 2026 2:49:30 PM

Across the pulp, paper, and packaging value chain, companies are accelerating practical solutions that cut plastic use, lower carbon footprints, and prepare for tightening global regulations. From large-scale foodservice and quick-service restaurant applications to specialty consumer goods and industrial transport, brand owners and converters are piloting and scaling bio-based materials, fiber-based formats, and circular design.

This month's round-up highlights recent initiatives that demonstrate how targeted innovation is reshaping packaging systems and advancing measurable progress toward more sustainable, low-carbon outcomes.

McDonald’s China Rolls Out Bio-Based and Paper Packaging Across 7,500 Restaurants

McDonald’s China has launched a nationwide upgrade of its food packaging, with more than 7,500 restaurants progressively transitioning to bio-based and paper solutions. The program replaces petroleum-based plastics with polylactic acid (PLA) and paper in cups, lids, and McCafé packaging, reducing plastic consumption by over 5,800 tonnes per year. By combining material innovation, enhanced customer experience, and rigorous food-safety standards, the initiative advances the adoption of lower-carbon, more sustainable packaging. Read more: www.mcdonalds.com

Mondi has partnered with bicycle manufacturer Polana Bikes to co-develop an innovative packaging solution that reshapes how premium bicycles are shipped and stored, while delivering a high-quality unboxing experience. The result is a smart, paper-based, and reusable system that combines Mondi’s corrugated packaging expertise with the ProtectorBAG – a pre-made paper bag designed to protect bikes and their components. ProtectorBAG shields key parts such as frames, handlebars, front wheels, and saddles from scratches, punctures, and dust during transport and storage. As part of Mondi’s re/cycle portfolio, ProtectorBAG can be easily recycled through existing paper waste collection and recycling systems across Europe. Read more: www.thepackagingportal.com

SCGP and Betagro Collaborate to Develop Sustainable Packaging Solutions Advancing Toward the Net Zero Target by 2050

SCGP is partnering with Betagro Public Company Limited to develop environmentally responsible packaging that supports both companies’ Net Zero emissions targets for 2050. The initiative emphasizes practical measures to lower environmental impacts, including reducing reliance on virgin raw materials, increasing the share of recycled content, and adopting packaging labeled under the Private Declaration Label for the Carbon Footprint of Products (CFP), certified by SCGP, to transparently report packaging-related greenhouse gas emissions. Together, these actions aim to enable sustainable business growth while generating long-term value for society and the environment. Read more: www.newsroom.scgpackaging.com

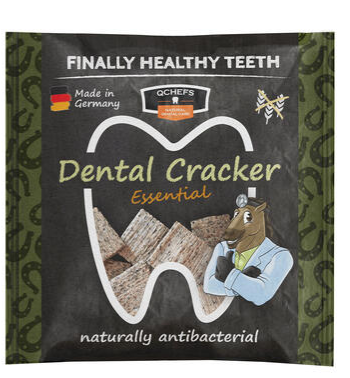

QCHEFS Revolutionizes Pet Care with Recyclable Paper Packaging from Koehler Paper

Koehler NexPlus® packaging papers are heat-sealable and provide reliable product protection through tailored barrier properties. Certified as recyclable according to the CEPI standard, they offer an environmentally responsible alternative to conventional plastic packaging. QCHEFS products using this solution are distributed across Europe via pet stores, pharmacies, veterinary clinics, and international online partners in more than 30 countries. Read more: www.koehlerpaper.com

Sabert Unveils Fully Compostable, PFAS-Free Pulp Packaging Range Ahead of EU Rules

Sabert Corporation Europe has introduced a new home-compostable and recyclable foodservice packaging range made from renewable, plant-based materials with no intentionally added PFAS. Engineered to satisfy tightening performance and regulatory demands, the HC range provides robust strength without the need for additional liners. Sabert has also unveiled Pulp Ultra, a next-generation PFAS-free formulation scheduled for launch next year, helping customers prepare for stricter EU packaging regulations coming into force in 2026. Read more: www.pulpapernews.com

Metsä Board LCA Shows Paperboard Takeaway Trays Can Deliver Negative Carbon Footprint

Metsä Board has finalized a third-party verified cradle-to-grave life cycle assessment comparing takeaway food trays made from MetsäBoard Pro FSB Cup paperboard with fossil-based polypropylene alternatives. Under typical European end-of-life conditions, the paperboard tray demonstrated a negative carbon footprint, while the polypropylene tray generated 0.112 kg CO₂e. The findings underline the climate advantages of renewable fiber-based materials, strong recycling performance, and the use of fossil-free energy in paperboard production. Read more: www.metsagroup.com

These developments illustrate both the momentum and the complexity of decarbonizing the pulp, paper, and packaging value chain. To explore these dynamics in greater depth, download our eBook "In the Green: Profitability and Sustainability in Pulp and Paper."

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)