When looking forward at the forces that are likely to drive the direction of the pulp and paper industry over the next 15 years, decarbonization and supporting a circular economy are at the top of the list. With this in mind, how do your current operations look as the call for the carbon transition grows louder? And what steps can you take to ensure your business will successfully decarbonize?

How Your Carbon Emissions Can Impact Your Company's Success

The global prioritization of sustainability continues to grow among consumers, investors, and buyers. Accordingly, carbon emissions from the production of pulp and paper can significantly impact the success of mills.

The shift towards ESG and decarbonization is influencing competitive positions across the industry. This move will create winners and losers, highlighting the importance of environmental performance in today's market landscape.

The industry will be affected in several ways:

- Business Risks: The ability to transition to a low-carbon economy is a long-term success indicator. Resistance to climate-related risks is important to mitigate.

- Compliance: Increasingly stringent ESG regulations cover a wider range of businesses—pulp and paper included. Access to markets will depend on a business’ regulatory compliance.

- Competitiveness: Product and business ESG credentials play a role in tenders and purchasing decisions.

- Financial Opportunities: Investors are showing a growing interest in assessing companies' transition strategies. With the enforcement of new regulations like the EU Taxonomy, there is a push towards incentivizing investments in sustainable practices with increased investor support and subsidies.

- Brand Perception: Society is placing an increased level of importance on sustainability. Perceived environmental credentials can impact consumer behavior and directly factor into earning potential.

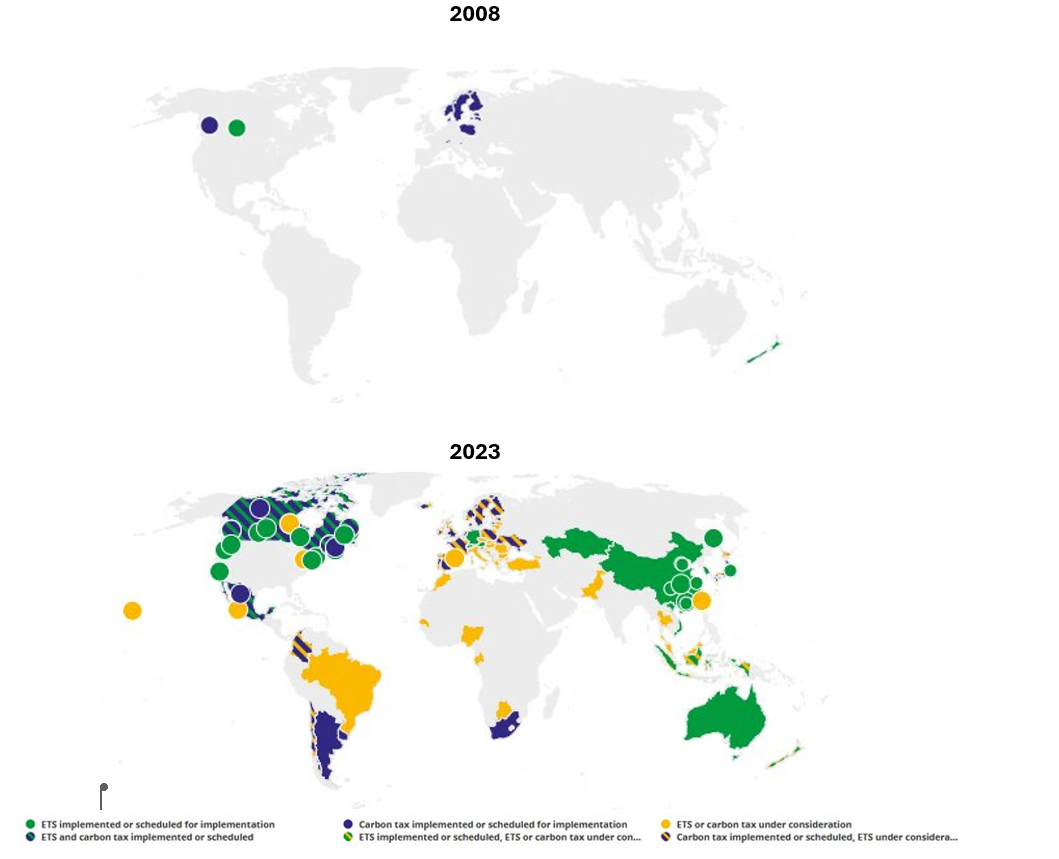

Alongside the growing pressure from consumers for businesses to reduce their emissions, government regulations have also significantly increased in recent years, as illustrated in the images below.

Government Regulations in 2008 vs 2023

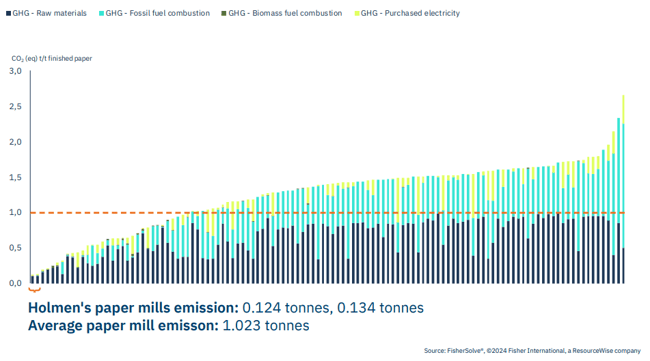

The discrepancy between the pulp and paper mill emitting the highest greenhouse gas emissions and the one with the lowest levels is substantial. Simply settling in the middle is no longer sufficient. Mills must now ascertain their position to align with regulatory requirements and uphold competitiveness in the market landscape.

To stay ahead in the industry, businesses require a tool that provides insights into how their emissions stack up against competitors. Companies need FisherSolve's Carbon Benchmarking module, an essential resource for comparing environmental performance among producers.

By utilizing comprehensive data on every pulp and paper mill globally, users can effortlessly compare the amount of CO2 emitted per ton by each mill. This data can be conveniently segmented to compare emissions to other mills based on major grade, geographical region, production capacity, and more. Together, this knowledge provides valuable insights for industry stakeholders.

Harnessing Market Intelligence to Drive Decarbonization Efforts

For suppliers and producers, access to FisherSolve’s data can serve as a powerful differentiator in the market. They can first use the tool to gauge their standing compared to other companies. Then, with the capability to dissect emissions by source, they can craft a robust carbon reduction strategy to propel them towards their environmental targets.

This transparent information not only aids in showcasing their commitment to sustainability but also appeals to a diverse range of stakeholders, including purchasers, CPG companies, and environmentally-conscious consumers. In a time where global emissions reduction is a top priority for businesses across all sectors, positioning oneself as a low-carbon entity can be a game-changer.

Purchasers within the pulp and paper sector can also leverage this valuable data to ensure they are sourcing from suppliers with the lowest emissions footprint. This becomes pivotal when companies self-report their emissions from cradle to gate, reinforcing their commitment to environmental stewardship.

Leveraging FisherSolve's Carbon Benchmarking Solution: Industry Example

One example of this data in motion is Holmen, a European paper manufacturer. The company utilized FisherSolve's Carbon Benchmarking module to determine that its Hallsta and Braviken mills boast the lowest CO2 emissions among all printing and writing paper facilities.

Surpassing the industry average of 1.023 tons of carbon per ton of finished paper, Holmen's two mills were found to emit a mere 0.123 tons and 0.134 tons per ton of finished paper. Armed with this data, the company can attract printing and writing paper buyers by showcasing their commitment to low emissions, ultimately aiding in reducing the industry's overall carbon footprint.

Read More on How Holmen Utilized FisherSolve’s Carbon Benchmark: FisherSolve database shows paper mills' carbon emission benchmark (holmen.com)

Empower Your Business Decisions with ResourceWise

At ResourceWise, we are dedicated to empowering our clients to make informed decisions by offering unparalleled data and analytics solutions. As the demand for companies and mills to adopt decarbonization strategies continues to escalate, our innovative solutions are here to guide you toward a sustainable future.

Explore our range of offerings to see how we can support your journey towards environmental excellence.

Urban Lundberg

Urban Lundberg