3 min read

How Industry 4.0 Technology Can Amplify Your Competitive Advantage

Savannah Franklin

:

Mar 30, 2022 12:00:00 AM

At the beginning of the year, Fisher International’s VP of Sales Matt Elhardt shared his predictions for the Pulp and Paper Industry in 2022. One of those predictions was for increased investment in Industry 4.0-related technology – but what exactly does that mean for the industry?

What is Industry 4.0 Technology?

Industry 4.0 refers to the fourth industrial revolution and, generally speaking, describes the growing trend towards automation and data exchange in technology and processes within manufacturing. Industry 4.0 technology is built upon nine pillars – Big Data being one of them.

According to the National Institute of Standards and Technology, Big Data is defined as consisting of “extensive datasets – primarily in the characteristics of volume, velocity, and /or variability – that require a scalable architecture for efficient storage, manipulation and analysis.” Companies can benefit from Big Data because it provides insights that can be leveraged to help improve operations, decision-making and other actions that can ultimately increase profits in nearly every area of supply chain management. According to a study in conjunction with the MIT Center for Digital Business, companies that inject Big Data and analytics into their operations can outperform their peers by 5% in productivity and 6% in profitability.

Industry 4.0 Technology in the Pulp and Paper Industry

Within the global Pulp and Paper Industry, the smallest changes along the supply chain can have cascading impacts. As participants in the P&P value chain plan for ongoing uncertainty, access to reliable insights at the local, national and global levels is imperative for confident planning and budgeting.

Purposeful, data-driven decision making imbues innovative businesses with an inherent competitive advantage. Business owners and managers who take advantage of Big Data and business intelligence resources can both aggregate massive amounts of data and refine it to address specific goals.

Some examples of different ways P&P industry participants can benefit from Industry 4.0 Technology include:

| Producers - Evaluate investment opportunities - Analyze cost and price sensitivity to macro-economic factors - Better anticipate the impact of global supply demand on your product mix |

Suppliers - Capitalize on changing supply and demand conditions - Plan for market capacity fluctuations - Track macro-economic factors for pricing impacts |

| Buyers/Financial Services - Evaluate growth trends by identifying macro-economic threats to investments - Plan for market capacity fluctuations |

Associations - Plan industry events to match changing industry dynamics - Analyze key member-specific markets |

How Can You Invest in Industry 4.0 Technology?

Fisher International uses strategic business intelligence to help customers increase performance via the FisherSolve Next BI platform. FisherSolve Next is the only database with integration and true data transparency for every mill, line and machine in the world.

In the world of Big Data, what separates Fisher International from other companies providing data service providers is the breadth and depth of what’s available within the FisherSolve Next platform:

- Intelligence Tab: Offers information on various lines, sites, companies, countries, regions and industries.

- Market Trends Module: Allows you to evaluate growth trends by paper grade and region, identify economic threats, prepare for market capacity fluctuations, and analyze cost and price sensitivity to macro-economic factors.

- Quality and Viability Index: Predicts the long-term future of pulp lines and paper machines by considering cost-of-production, size, technical age, grade risk, position in company fleet, capital required, transportation, and other factors all of which can be considered under various economic scenarios.

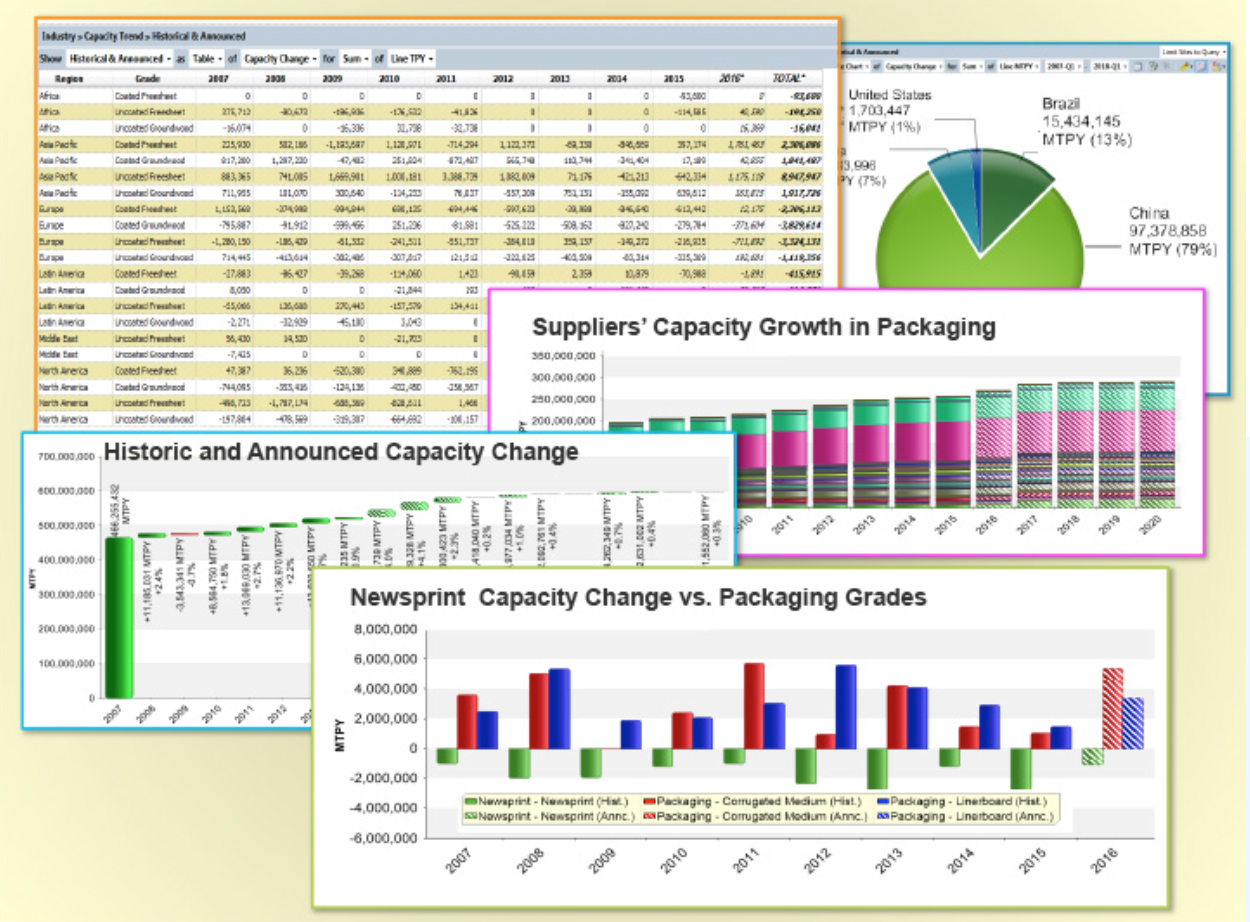

- Capacity Trends Module: Allows you to see how each machine’s products and capacity have evolved over time, along with detailed data so you can draw strong strategic conclusions.

- Carbon Benchmark: Shows the carbon output of every pulp line and paper machine for each of the products they produce, all the way from cradle to destination.

- Water Supply Benchmark: Shows water and wastewater flows for each mill with data about volume, source, application, destination, and treatment methods for each site’s incoming water, outgoing wastewater, and sludge – which is used to measure water consumption per ton and compare it to the mill’s water risk.

- Installed Costs: Shows replacement costs, also called installed costs, of every major unit operation in every mill in the world in order to help understand the magnitude of investment that would be required to bring each asset up to current standards.

Sustainable profits come from the value gained through constant refinement of utilized assets. In commodity businesses like pulp and paper, that effectiveness is driven by a wide range of decisions which, when made marginally better, result in higher prices, higher operating rates, lower costs, and lower volatility than in less well-run firms.

While capital investment is the cost of entry, profitability comes from superior decision making. Industry 4.0 is the next step in uncovering the insights necessary to drive tactical, meaningful, and profitable business decisions.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)