7 min read

From Importer to Exporter: An Overview of Brazil's Tissue Industry

Bruce Janda

:

Dec 5, 2023 12:00:00 AM

Bruce Janda

:

Dec 5, 2023 12:00:00 AM

Portuguese-speaking Brazil managed to avoid the fragmentation experienced by the Spanish-speaking countries of Latin America during the colonial period. This allowed Brazil to maintain its size and preserve its unique culture. By staying united, Brazil was able to tap into a wider range of natural resources and climates for development compared to its smaller neighboring countries. However, this unity also gave rise to a distinct tissue culture.

Brazil's tissue production and exports continue to expand each year, with the country transitioning from a tissue importer to an exporter in 2021, after the pandemic. As a global leader in tissue pulp, Brazil takes advantage of its sub-tropical eucalyptus plantations to maximize the value of its fiber resources through increased tissue production for both domestic consumption and exportation.

While this strategy allows Brazil to make the most of its efficient plantations and pulp mills, it does come with higher shipping costs and a larger carbon footprint. Unlike packaging paper or market pulp grades, soft and bulky tissue products occupy a disproportionate amount of shipping containers or cubic meters compared to their weight.

A Quick Look at Brazil’s Demographics and Economy

With an estimated population of 218,689,757 in 2023, Brazil stands as the sixth most populous nation in the world with the seventh largest land mass globally. As depicted in Figure 1, the population trend is represented by a yellow line. Although the population growth rate is projected to be 0.64% in 2023, Brazil's slowing population growth has prompted the country to seek manufacturing growth through tissue exports. Furthermore, Brazil benefits from a relatively young workforce compared to more developed nations.

Figure 1: Brazil's GDP per Capita and Population

Source: FisherSolve

In 2021, Brazil's economy experienced a robust growth rate of 4.62%. Figure 1 illustrates this growth in GDP per capita, enabling a global comparison at purchasing power parity. The post-Covid-19 recovery and subsequent growth are also depicted in Figure 1.

Notably, personal income saw significant increases in both 2021 and 2022, providing a strong foundation for further expansion in the domestic tissue market, particularly in alternative formats like paper towels.

Brazil’s recent experience with unemployment and inflation is shown in Figure 2. Inflation hit a peak in 2022, but 2023 data indicates some improvement, along with unemployment. These trends should help further support the development of domestic tissue demand.

Figure 2: Brazil's Inflation and Unemployment

Source: FisherSolve

Import and Export Trends

Figure 3 shows Brazil’s tissue import trend. Tissue imports dropped dramatically since 2013. Recently, Columbia and China supplied the largest share of imports, with smaller amounts from South Korea, Germany, and the United States. Its import volume in 2022 was about one-sixth of the rate in 2007.

Figure 3: Brazil's Tissue Import Trend

Source: FisherSolve

Source: FisherSolve

Brazil’s tissue export trend shows strong growth, as seen in Figure 4, as tissue exports now greatly exceed imports. The 2022 import volume is about 3.5% of the 2022 export volume. Brazil’s tissue export customer focus includes its Latin American neighbors of Chile, Argentina, Uruguay, and Paraguay, with lesser volumes to Mexico.

Figure 4: Brazil's Tissue Export Trend

Source: FisherSolve

Brazil’s Tissue Growth

Brazil has added significant tissue capacity since 2007. Total tissue capacity by 2025 is expected to reach more than 2.2 times the 2007 level, as more new capacity is coming online in 2024. This is supported by Figure 5, which shows the country’s tissue machine count change trend for the referenced periods.

Figure 5: Brazil's Tissue Machine Count Change

Source: FisherSolve

As we can see, it indicates that seven new machines are under construction. The count change chart tends to understate the impact as the new machines represent a much larger capacity than the old machines going out. For lower costs, several new machines will be located at virgin integrated or recycled integrated fiber sites. Most of Brazil’s tissue production is still consumed at home, and the increased exports represent a small portion of the total capacity so far.

Brazil's eucalyptus is globally recognized as a vital component in the tissue industry, contributing to the softness and premium quality of tissue products for higher profit margins. Eucalyptus possesses unique properties that enhance tissue formation and promote the development of free fiber ends on the tissue surface.

Surprisingly, however, only a mere 12% of Brazil's total tissue capacity is currently produced at integrated virgin pulp sites. This would allow the country to capitalize on energy and cost savings by eliminating the need to dry market pulp for transportation.

Figure 6 shows the breakdown of the country’s tissue capacity by site type. Surprisingly, 58% of Brazil’s tissue capacity is located on recycled integrated fiber sites that accrue the same cost savings.

Figure 6: Brazil's Tissue Machine Capacity by Site

Source: FisherSolve

Consumer bath tissue is the most significant product produced by Brazil’s tissue mills. This indicates a lot of room to grow tissue consumption with improved consumer spending power, leading to increased use of disposable napkins and towels in the home.

Figure 7 shows each finished product category’s average use of fiber types. Very little softwood is produced or used in tissue by Brazil. This could be a tissue quality or performance issue for competitive tissue exports from the country, as softwood is a crucial ingredient for strength and bulk. However, the newer tissue machines located at the eucalyptus-integrated fiber sites appear more focused on exports.

Figure 7: Brazil's Tissue Furnish by Finished Product Type

Source: FisherSolve

In Figure 8, we can observe the breakdown of the fiber composition in finished tissue products, specifically focusing on eucalyptus virgin fiber integrated sites with the newest tissue machines. This information serves as a valuable guide for global tissue manufacturers who import eucalyptus market pulp, helping them determine the optimal use of fiber in different tissue products.

Figure 8: Brazil's Tissue Furnish by Finished Product Type for Virgin Integrated Fiber Sites Only

Source: FisherSolve

For instance, commercial napkins and towels consist of 100% eucalyptus hardwood fiber, while commercial bath tissue includes eucalyptus fiber in the form of BCTMP, along with a small amount of softwood pulp. Retail bath tissue utilizes 18% softwood pulp and 16% BCTMP, likely for added bulk and strength. Consumer napkins and toweling contain even higher percentages of BCTMP and some softwood. However, it is worth noting that using 100% eucalyptus may be more cost-effective.

Nevertheless, incorporating strategic amounts of other fibers can optimize tissue properties in exported products, leading to increased profitability despite the additional costs.

How Does Brazil Compare Against Other Countries?

A comparison set of countries’ tissue machine fleets was chosen based on the regional customers of Brazilian exports, including Argentina, Columbia, and Uruguay. Tissue exporters such as Mexico, Turkey, China, and the United States were also included for comparison.

The bubble chart in Figure 9 shows the average quality of the comparison set and Brazil. The size of the bubbles on the graph represents the total tissue capacity for each country. The X-axis represents each country’s average machine technical age, and the Y-axis represents the average machine width.

Figure 9: Brazil's Tissue Machine Quality Comparison

Source: FisherSolve

Brazil’s tissue machines are of average technological age while also being narrow. Compared to Indonesia, they average 5-6 years older and almost 100 cm narrower. However, Brazil is updating its tissue machine fleet faster than most countries on the chart, and we should expect continued improvement in these metrics.

The relative average cost of making a finished ton of tissue for the countries in the comparison set is shown in Figure 10. The height of each country’s bar represents the cash cost of production, and the width of each bar is the relative tissue capacity. The colored bands for each bar represent the costs of raw fiber material, market pulp, chemicals, energy, labor, materials, overhead, and credits.

Figure 10: Brazil's Relative Tissue Production Cost vs Export Partners

Source: FisherSolve

Brazil stands out as one of the most cost-effective countries for tissue production, alongside Indonesia and Argentina. On the other hand, Mexico and the United States face significantly higher average costs. Notably, Mexico's energy costs are particularly steep, while labor costs in the United States are also considerably higher. It is worth mentioning that these cost comparisons are based on averages, and the individual costs of each machine can vary greatly.

A snapshot of the average tissue machine and mill viability is shown in Figure 11. In this case, the bar height is detailed by viability factors.

Figure 11: Brazil Tissue Machine Viability vs Other Countries

Source: FisherSolve

Brazil’s tissue production does well in this comparison, as is positioned on the lower end of the benchmark. However, Columbia and Uruguay are in the high-risk group with lower viability, two countries that have started to import Brazilian tissue.

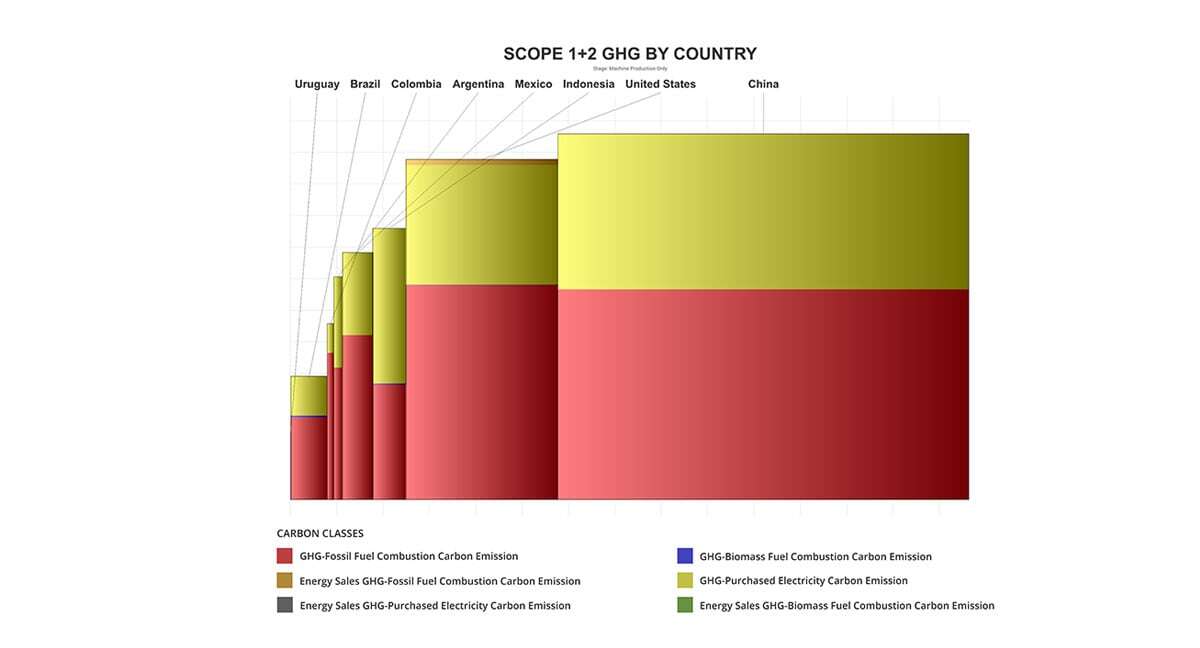

Carbon emissions per finished metric ton are shown in Figure 12. These are the emissions of the tissue machines only on a site and do not include pulp production on an integrated site. Scope 1 and 2 emissions were chosen as the most likely to be included in a carbon analysis by potential consumers. The colors stacked in each bar represent the source of each emission.

Figure 12: Brazil's Carbon Emissions Per FMT, Scope 1&2

Source: FisherSolve

Uruguay and Brazil produced the best results in this chart. Whereas China and the United States on the other hand lag behind, positioned as the worst performers in this set. It's important to note that carbon emissions are influenced by multiple factors, including the choice of electric grid power or mill heat source, ranging from coal to natural gas. Additionally, the energy efficiency of each machine used to produce a ton of tissue also plays a significant role in determining carbon emissions.

To Sum It Up...

Brazil is making significant progress in transitioning from being a tissue importer to becoming a tissue exporter, with a strong focus on selling to its Latin American neighbors. This strategic move allows Brazil to leverage its competitive advantages in the region.

Furthermore, the country's domestic economy continues to support the growth of consumer tissue consumption, paving the way for further development in this sector. The addition of new tissue capacity will only accelerate these positive trends. While Brazil effectively utilizes its recycled integrated tissue sites, there is still ample room for expansion at its eucalyptus pulp-producing sites.

By capitalizing on these opportunities, Brazil can capture synergies and cost savings, enabling the production of premium exportable tissue products. The existing eucalyptus fiber integrated machines have already demonstrated their ability to optimize critical grades by incorporating BCTMP, resulting in enhanced bulk and cost savings.

Additionally, the inclusion of small amounts of softwood pulp ensures strength and bulk in the final products. Notably, there is a significant fiber synergy between Argentina and Uruguay, as they produce southern softwood pulps that further enhance the quality of high eucalyptus tissue furnishes.

To fully understand Brazil's competitive position in the tissue industry, it is crucial to delve into the specifics of tissue producers and individual machines. While this article provides a comprehensive snapshot of Brazil's tissue industry as it stands today, it is important to recognize that the landscape is constantly evolving. Factors such as fiber prices, exchange rates, and environmental regulations are subject to change, which can present both advantages and challenges for industry participants.

Additionally, Brazil's tissue mills are likely to undergo transitions and consolidation, while neighboring countries may also invest in their own tissue-making capacity, ultimately impacting Brazil's imports and exports in this sector. The dynamic nature of the tissue industry highlights the need for ongoing analysis and adaptation to ensure a competitive edge.

Download a copy of our 2022 Global Tissue Industry Study Report

Curious about what else FisherSolve has to offer? Learn more.