4 min read

Decision-Making Optimization: Gaining a Competitive Edge in Pulp and Paper

Matt Elhardt

:

Nov 7, 2023 12:00:00 AM

Matt Elhardt

:

Nov 7, 2023 12:00:00 AM

Maintaining a competitive advantage in today’s dynamic pulp and paper industry is essential for success. However, optimizing business decisions in this complex and mature market can be challenging. Generic optimization solutions often fall short due to their lack of industry focus.

In this blog post, we will be introducing EDGE (Enterprise Decision Guidance and Execution), a modern modeling platform designed specifically for the pulp and paper industry. Let's explore how EDGE can empower companies to make well-informed decisions, overcome challenges, and unlock their maximum potential.

The Challenge of Optimization in the Pulp and Paper Industry

Staying ahead of the competition in the pulp and paper industry requires insightful decision-making and swift action. Companies often struggle to make optimum decisions—such as capital to spend, what products to make, and how much to buy—due to the complexity and the unique characteristics of each mill.

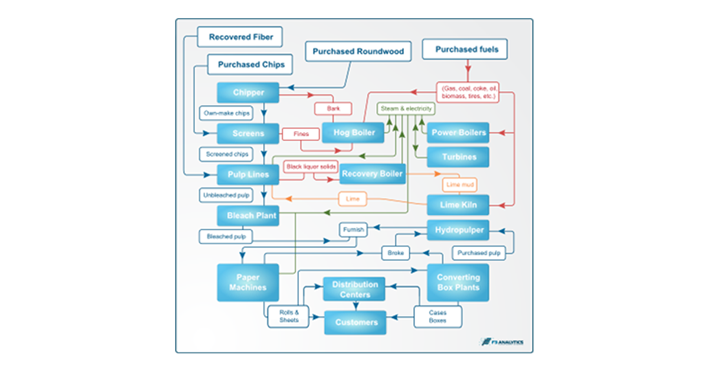

Pulp and paper mills are a ‘system of systems,’ each with distinctive bottlenecks, performance characteristics, and cost profiles. However, many rely on linear optimization through generic software tools and spreadsheet models. These solutions come with their own set of problems, which can include:

- Software that is not specific to the industry and therefore requires significant investment to customize to meet a mill’s business needs.

- Starting with a blank model that needs to be populated with data, which can be extremely time-consuming.

- Working with a vendor with little experience in the pulp and paper industry, resulting in more internal time spent on the analysis.

What You Can Achieve with Optimization

By staying ahead in the market and optimizing business decisions, companies can differentiate themselves from competitors. Companies can achieve this through superior product quality, cost efficiency, sustainability initiatives, and more. The benefits? Companies can attract and retain customers, secure long-term contracts, and withstand market fluctuations. In our experience, it is typical for the average pulp mill to generate several million in EBITDA opportunity per year through optimization.

EDGE: Empowering Pulp and Paper Companies

ResourceWise, in partnership with F3 Analytics, created EDGE (Enterprise Decision Guidance and Execution) to provide pulp and paper mills with an industry-specific optimization tool for decision-making support. It enables users to make informed decisions and navigate complex challenges with confidence. Its functionalities include:

- Optimizing operations across a mill network to maximize cash.

- Synthesizing production from fundamental engineering parameters.

- Conserving fiber mass and energy.

- Integrating fiber, energy, and financial views.

Optimization offers significant leverage. And the optimization you receive from EDGE is multifaceted and can be used to address challenges in three core areas:

1. Strategy

Effective strategic decision-making is the backbone of any successful company. It can make or break a business’s success and unlock growth potential. EDGE empowers customers to evaluate critical system-level issues such as capital investments, mergers and acquisitions, facility integration or divestment, and closing facilities.

A standout strength of EDGE is its seamless integration of fiber, energy, and financial views of the production system—assisting in optimization across the entire value chain from raw material procurement to the delivery of converted products. This integration breaks down silos within an organization, fostering collaboration and enabling comprehensive decision-making.

2. Operations

Operational efficiency is essential for maintaining competitiveness and profitability. The EDGE modeling system builds your business from fundamental engineering parameters with data collection kickstarted and streamlined by leveraging our FisherSolve database.

Each analysis evaluates the production system as a whole, simultaneously optimizing across the typically siloed operational areas of the powerhouse, pulping, and papermaking. It accomplishes this all while maximizing EBIT based on true marginal economics rather than assumed average costs. As a result, you can address challenges like debottlenecking, adapting to changing product specifications, and deploying new technologies knowing that no ripple effect is overlooked.

3. Planning

Effective planning is crucial to minimizing risk and maximizing returns. The pulp and paper industry is no stranger to disruptive events and changing market conditions. When opportunities or challenges arise unexpectedly, being prepared and equipped is critical.

EDGE allows users to develop robust plans with contingencies for business risks, interruptions, and price volatility. By quantifying whole-system impacts across different business units, mills, brands, interests, projects, and priorities, EDGE enables organizations to navigate uncertain market conditions with confidence.

EDGE optimization combines physical operations and choices with input and market economics. As we can see in the image below, numerous moving parts need to be accounted for. That’s why choosing a platform made specifically for the pulp and paper industry is so crucial.

A Hypothetical Scenario: Unleashing the Power of EDGE

To better understand how EDGE can significantly enhance your business optimization, let’s explore a hypothetical case study.

Imagine a major integrated mill that wants to complete a capital project analysis. This particular project involves considering different investment options, amounting to $300M, for the mill’s back-end operations. These include evaporators, a recovery boiler, BFB construction, and turbines, all of which can be arranged in various configurations.

Using EDGE, we can create over 50 scenarios and assess the potential returns under different fuel costs and fiber cost curves. This process helps us pinpoint the most favorable course of action for the mill.

By using EDGE, the integrated mill can identify solutions that promise high returns and are resilient to economic conditions. For instance, they may find investing in an evaporator project yields substantial benefits, while replacing specific high-capital boilers and turbines might not be as valuable. This optimized business plan not only instills utmost confidence in their decisions but also frees up staff resources that were previously entangled in similar analysis.

EDGE was purpose-built for the pulp and paper industry by pulp and paper industry professionals, ensuring that clients benefit from domain expertise and specialized knowledge. Unlike generic optimization and consulting services, EDGE addresses the nuances, challenges, and opportunities unique to the industry, allowing for more accurate analysis and recommendations that align with the specific needs and goals of pulp and paper companies.

EDGE empowers organizations to make informed decisions across multiple critical business areas unlocking operational efficiency, minimizing risks, and enhancing profitability. Embrace EDGE and gain the competitive edge you need to thrive in the pulp and paper industry.

If you're ready to differentiate your pulp and paper company from competitors, contact us to explore how EDGE can elevate your business to new heights.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)