5 min read

Waste, a misplaced resource: Harnessing Earth’s replenishable reserves

Tecnon OrbiChem

:

Apr 4, 2023 12:00:00 AM

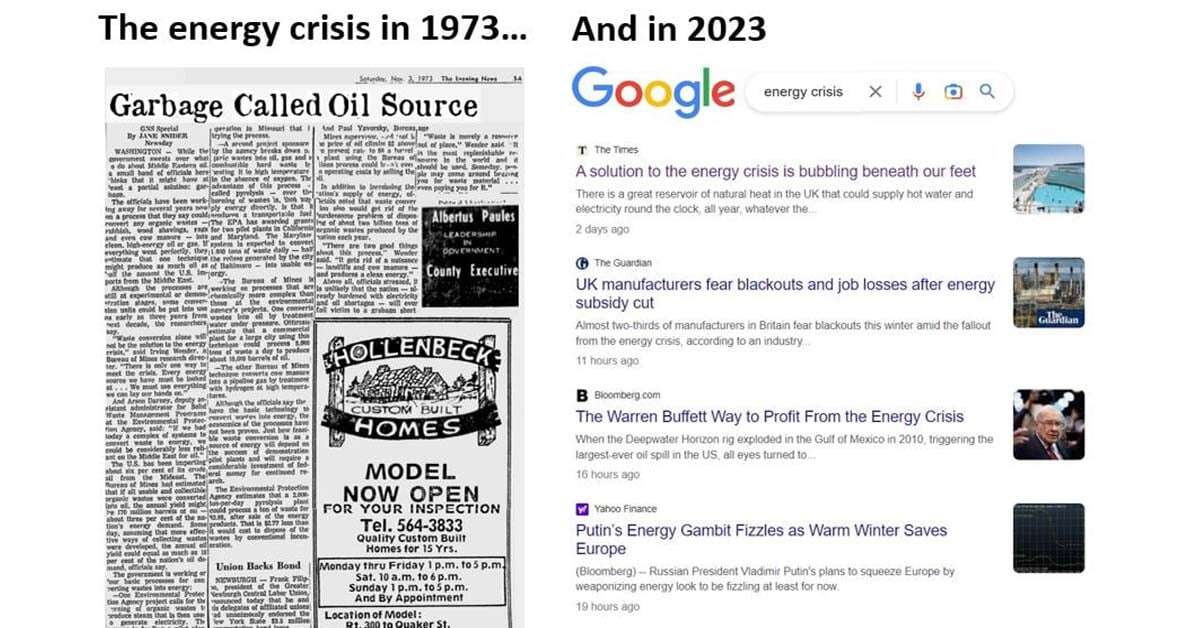

The term ‘unprecedented times’ has become almost synonymous with the 2020s. Outside of most living people’s memory, it is all too easy to imagine the influenza pandemic – which killed an estimated 50 million people after its outbreak 101 years before Covid-19 – didn’t happen at all. And today’s so-called energy crisis can feel like a post-millennium problem given the politicised nature of oil and gas supply.

But a 50-year-old newspaper article referencing ‘government sweats over what to do about middle eastern oil’ and an ‘energy crisis’ in full swing firmly dispels any notion that the world is facing unprecedented times today.

The compelling article focuses on four basic processes for converting wastes – including municipal solid waste (MSW) – to energy, biofuel or chemical feedstock. The projects include a pyrolysis approach and burning organic waste to produce steam and generate electricity. Both were supported by the Environmental Protection Agency (EPA).

Two more chemically-inspired projects were being developed by the Bureau of Mines – a scientific agency dissolved in the 1990s following eight decades of service as a US Department of the Interior unit. One project aimed to convert waste to oil using water pressure techniques while the other was designed to convert cow manure into a pipeline gas using hydrogen at high temperatures.

In a statement that remains as relevant today as it was in 1973, Bureau of Mines research director Irving Wender described waste as ‘merely a resource out of place'.

'There is only one way to meet the energy crisis. Every energy source we have must be looked at...

We must use everything we can lay our hands on'

Irving Wender, Research Director, Bureau of Mines

‘There is only one way to meet the energy crisis,’ he told the newspaper. ‘Every energy source we have must be looked at... We must use everything we can lay our hands on.’

The bureau estimated that if all usable and collectible organic wastes were converted into oil, annual yield would be 170 million barrels – 3% of the then current demand. It could, the bureau’s officials believed, increase to 18% with more efficient collection process.

:

:

Pyrolysis potential

According to EPA estimates at the time, a 2000 ton per day plant could process a ton of waste more cheaply than incinerating it, after sale of the energy products yielded that is. That’s not exactly an attractive return on investment for private enterprise, however, energy and petrochemicals giant Shell is keen to cash in on the potential of pyrolysis. And Shell is not alone, as explored in our earlier blog post and white paper Pyrolyis projects on a hot investment streak.

Off the back of its plan to bring a new 50 ktpa pyrolysis plant onstream in Singapore this year, Shell has provisionally agreed to supply ethylene derived from plastic waste to Mitsui Chemicals Group. The ethylene – a basic chemical produced in greater volumes than any other – will be used to make polyethylene.

Free eBook download:

Methanol and hydrogen: Investments surge in renewable drop-in alternatives

Another of the largest volume chemicals produced globally is methanol feedstocks. Methanol underpins the manufacture of compounds including acetic acid and formaldehyde and end products such as plastics, foams, adhesives and solvents.

Global trade association the Methanol Institute estimates production at around the 100 million tpa mark worldwide, nearly all of which is produced using natural gas or coal. It is currently tracking over 80 renewable methanol projects worldwide which – if realised – will deliver over 2.7 billion gallons of biomethanol and eMethanol annually by 2027, the organisation says.

Biomethanol is a potential source for powering fuel cell electric vehicles. And eMethanol – which combines biomass-derived CO2 with hydrogen in a water electrolysis process – is being developed by companies including ExxonMobil for use as a sustainable aviation fuel (SAF).

Trash-derived syngas

Among the projects with potential to meet the growing demand for methanol sustainably is Sierra Energy, a Californian company founded in 2004. It developed a gasification technology that converts trash to energy without burning.

Designated FastOx, the company’s system breaks both organic and inorganic waste down at molecular level using heat, steam and oxygen. Without creating any further waste streams, according to the company, Sierra Energy’s process yields a particulate and tar-free syngas that can be converted into high-value end products including methanol.

Municipal solid waste: Resource without end

The world’s first commercial scale waste-to-methanol facility was built by Enerkem in Canada. Enerkem also converts non-recyclable MSW into ethanol and other widely used chemical intermediates. The company developed a gasification technology to recycle carbon from waste materials. Candidate materials are defined as non-recyclable, non-compostable, end-of-life material destined for landfill or incineration. They include textiles, non-recyclable plastics, wood residues, or soiled food containers.

The carbon within the waste is transformed into a clean gas, which is then upgraded. Drawing on its two-decades’ experience, Enerkem recently developed a SAF with a chemical composition matched to the fossil-based jet fuel kerosene but with a 93% carbon intensity reduction. Enerkem’s sustainable fuel source was awarded the Sky's the Limit Challenge grand prize hosted by government department Natural Resources Canada in 2022.

Enerkem’s executive vice president engineering, innovation & operations Michel Chornet said interest in Enerkem’s process was growing. It’s a ‘second generation of sustainable aviation fuel as opposed to first generation SAF like that developed from used cooking oil for example’.

‘The growing interest in Enerkem’s technology is due to the first pathway – such as fuels produced from used cooking oil – representing ‘a finite pool’ in terms of resource. There's only so much residual oil out there,’ Chornet adds.

Circular chemicals

Enerkem joined an EU-funded collaboration to revolutionise MSW management – Ecoplanta Molecular Recycling Solutions aims to deliver circular chemicals. Alongside Spanish multinational energy and petrochemical company Repsol and water/waste management expert Agbar, Enerkem is building a plant in Tarragona, Spain. The plant will process around 400 ktpa of non-recyclable MSW to produce 220 kt of methanol and is projected to be in operation in 2025, according to the press release.

In the Netherlands, Enerkem collaborates with Shell Chemicals, Air Liquide, Nouryon and Port Rotterdam to produce 220 kt of methanol using non-recyclable MSW.

Transatlantic trash trajectory

Fulcrum BioEnergy – a US-headquartered company – designed a process combining gasification and Fischer-Tropsch technologies to convert black bin bag waste to drop-in SAF. The Company's Sierra Biofuels plant in the US state of Nevada started up in December 2022.

In the same month, Fulcrum was awarded £16.7 million from the UK government’s Green Fuels, Green Skies award scheme and has earmarked 2027 as the start up date for an 83.7 ktpa plant in the northern port of Ellesmere.

Its process yields a carbon monoxide and hydrogen-based feedstock that is turned into a SAF with a 100% reduced greenhouse gas emission rate, says the company.

Altalto – a co-investment between Velocys and airline British Airways – is building a waste-to-jet fuel plant with Green Fuels, Green Skies funding. Using technology developed by spinouts from the UK’s University of Oxford and the Pacific Northwest National Laboratory in the US, the pair are set to open a commercial waste-to-SAF plant in Immingham, UK with funding up to £27 million from the UK Department for Transport.

Earmarked to annually process hundreds of thousands of tons of non-recyclable everyday household and commercial waste [otherwise] destined for landfill or incineration into SAF. A net GHG saving of around 70% per ton of conventional fuel displaced is projected.

One advantage of using MSW is that it can be sourced free-of-charge from waste management companies keen to avoid the cost of incineration – as referenced by the article and EPA projections half a century ago – or landfill taxation in the UK specifically.

Another advantage is the credits available in some jurisdictions for the low carbon or even carbon negative fuels that result with some of the conversion technologies used.

The free-to-download whitepaper Methanol and hydrogen: Investments surge in renewable drop-in alternatives that accompanies this blog post was produced by Tecnon OrbiChem's Biomaterials expert Doris de Guzman. The original report was made available to OrbiChem360 Biomaterials subscribers in October 2021. It contains insight into a number of methanol, hydrogen and carbon dioxide-based feedstock innovations.

Besides companies referenced in this blog post, the eBook explores Methanex, BASF, BioMCN, Carbon Recycling International, Perstorp, Södra, Gidara Energy, Siemens Energy and Haldor Topsoe.

Nel ASA, ENGIE Solutions, Uniper Energy, Colruyt Group, DEME (offshore energy service provider), alkaline electrolyser producer John Cockerill, Italian gas group SNAM, as well as Italy’s Saipem and Alboran.

US-based hydrogen solutions provider Plug Power, clean hydrogen producer Monolith Materials, NextEra Energy Resources and Perry Creek Capital.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)