7 min read

Removing carbon dioxide from the air: Direct air capture

Charles Fryer

:

Sep 4, 2023 12:00:00 AM

Charles Fryer

:

Sep 4, 2023 12:00:00 AM

Direct Air Capture (DAC) of CO2 has hit headlines recently. A concept related to strategies of carbon capture and storage (CCS) and carbon capture and usage (CCUS)—which together are known as carbon capture and utilization and storage (CCUS)—but DAC involves the capture of air in any location whereas CCS and CCUS use air emitted at the point of emissions, such as a chemical plant.

The idea of DAC is to slow down or stop climate change by extracting carbon dioxide from the air and burying it in the ground or converting it into useful products.

It is a beguilingly simple concept. In practice, it is fiendishly difficult to achieve except at high cost because the concentration of CO2 in the air is only about 400 parts per million (ppm).

However, the potential rewards of establishing a low-cost and technically successful venture are attracting many companies and organizations to invest in projects they hope to make commercially viable. The major endeavors are taking place in the US, stimulated by a generous support program.

Funding Carbon Capture

The major source of support is the oddly named Inflation Reduction Act, passed in August 2022. Its main components are tax credits and funding to incentivize green energy projects.

Many of its subsidies are uncapped, meaning that, depending on how many projects are put forward by the private sector, its climate spending could ultimately cost anywhere from US$369bn (the government’s projection). There are tax credits labeled 45Q for industrial facilities and power plants that capture and store CO2, which provide up to US$85/ton per ton credit for CO2 permanently stored and up to US$60/ton for CO2 consumed industrially.

Also, under 45Z, tax credits are available for the sale of low-carbon transportation fuels, such as SAF. These credits will be available for the next 12 years.

Another source of funding comes from the US Bipartisan Infrastructure Law, under which the Department of Energy (DoE) has allocated US$3.5 billion over the next five years for investments in DAC technology.

DAC technology is considered underdeveloped at present and needs support to scale up plant size so as to reach commercial viability. The DoE announced in August that two projects would be assigned a total of US$1.2 billion to develop DAC technology on an industrial scale:

- Project Cypress in Louisiana, run by Ohio-based firm Battelle, Swiss company Climeworks Corporation and Heirloom Carbon Technologies;

- The South Texas DAC Hub in Kleberg County, Texas. It was proposed by Occidental Petroleum (Oxy) subsidiary 1PointFive and partners Canadian clean energy company Carbon Engineering, and Australian engineering services company Worley.

The DoE also launched several new initiatives aimed at bringing the cost of the DAC technology down to less than $100 per metric ton of CO2 equivalent within this decade.

Battelle plans to use DAC technology developed by Climeworks and Heirloom at a location in Louisiana. Climeworks currently owns the biggest DAC facility in the world, located in Iceland, which removes around 4,000 metric tons of CO2 each year.

Heirloom is a California-based environmental services start-up using limestone to remove CO2 from the air. Battelle is also partnering with Gulf Coast Sequestration to manage the storage of the CO2 underground. The target is to sequester a million tons per year by 2030.

Oxy’s operations will be developed on 106,000 acres of land south of Corpus Christi. Once fully operational, the target is to remove up to 30 million metric tons of CO2 every year using DAC technology.

A huge array of fans will force air through a CO2 capture device. The CO2 will then be recovered and pumped thousands of feet underground into geological formations, where it can remain for hundreds of years.

Capturing CO2 Directly From The Atmosphere

Two approaches are currently being used to capture CO2 from the air: solid and liquid DAC. Solid DAC (S-DAC) is based on solid adsorbents operating at ambient pressure or under a vacuum and medium temperature (80-120 °C).

One version uses Zeolites as the absorption medium. A DAC plant relying on zeolites was commissioned in 2022 in Norway, with plans to scale the technology up to 2,000 metric tons of CO2/year by 2025 through the project Removr.

Liquid DAC (L-DAC) uses an aqueous basic solution (such as potassium hydroxide) to absorb CO2 as a chemical compound. The compound is then released by subjecting it to high temperatures (between 300 °C and 900 °C).

The CO2 is recovered by reversing this reaction using renewably powered kilns.

Passive DAC Potential

A process that is intermediate between S-DAC and L-DAC is Passive DAC, which uses calcium hydroxide to absorb atmospheric CO2 by combining the two to form CaCO3.A more radical approach is Electro Swing Adsorption DAC, which employs an electrochemical cell in which a solid electrode adsorbs CO2 when negatively charged and releases it when a positive charge is applied.

Capturing CO2 from the atmosphere through DAC is currently very energy intensive since the concentration of CO2 in the atmosphere is very low, around 400 parts per million (ppm), far lower than, for example, the emissions of a power station or a cement plant.

Both S-DAC and L-DAC operate using both heat and electricity. S-DAC can be powered by various renewable or low-carbon energy sources, such as heat pumps, geothermal, nuclear, solar thermal, or biomass-based fuels. In the case of L-DAC, however, the current high-temperature needs of today’s technology require the use of low-carbon fuels, such as biomethane or renewables-based electrolytic hydrogen. It is hoped that, in the future, the L-DAC will operate solely on electric energy.

How Necessary is DAC?

In spite of the air of respectability conferred on DAC by the funding now lavished by the US Department of Energy, some environmental activists are concerned by the moral hazard involved. Fossil fuel companies could use the prospect of DAC's commercial viability to backslide on their public pledges to move to low-carbon operations. In the limit, it becomes an excuse to do nothing to reduce carbon emissions, as DAC will surely solve the problem...

Other environmental activists take a more nuanced approach. They are skeptical of the contribution that DAC can make but acknowledge that a multiplicity of technologies must be developed for global climate targets to be met since the eventually successful approaches cannot be identified at the present stage of development.

Other experts are highly skeptical of DAC, regarding it as not only a futile pipe dream but a danger that is diverting funding and effort from other technologies for carbon abatement that are far more likely to be successful. Some climate change experts have labeled DAC as “Greenwashing at its worst” and even as “the most dangerous idea in the world.”

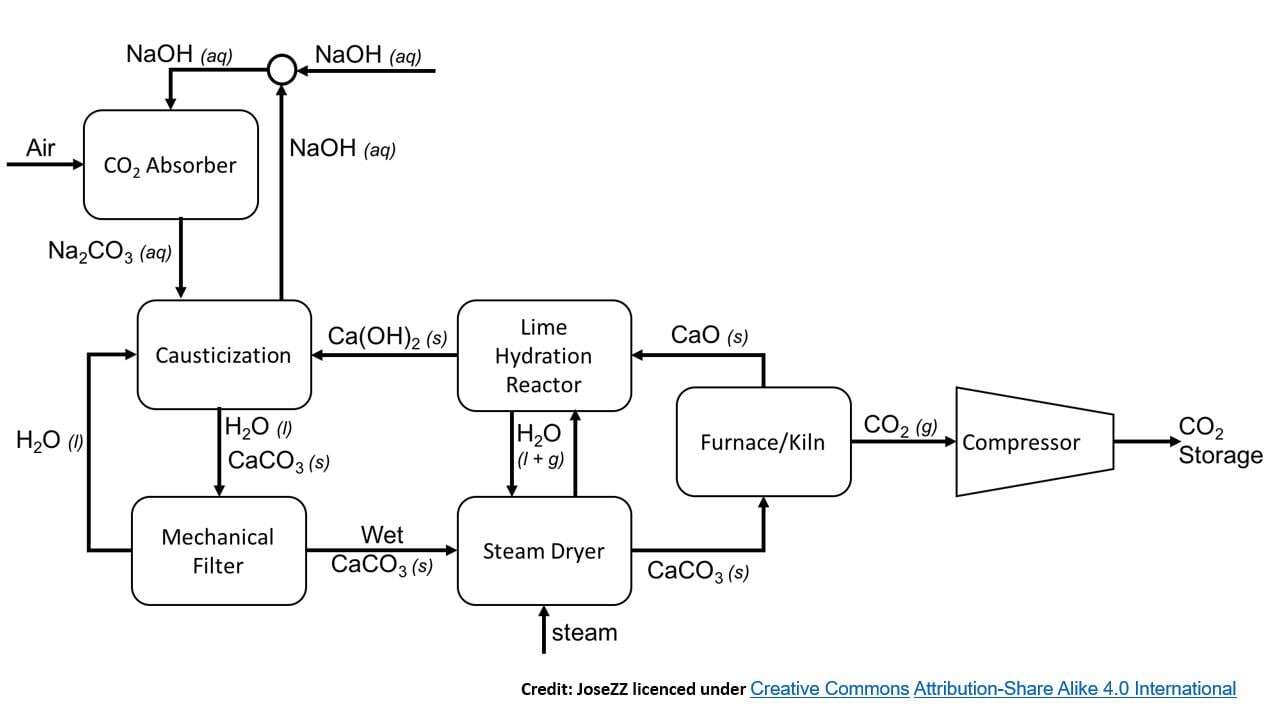

The flow diagram below shows a DAC process using caustic soda as the absorbent. The diagram also includes a solvent regeneration step.

Source: JoseZZ Creative Commons Attribution-Share Alike 4.0 International

Direct Air Capture: The world's most dangerous idea: ABLC Connect Webinar

A recent webinar organized by ABLC Connect, with  bioeconomy daily The Digest editor Jim Lane as moderator, brought together the views of the experts in ABLC’s Due Diligence Wolfpack.

bioeconomy daily The Digest editor Jim Lane as moderator, brought together the views of the experts in ABLC’s Due Diligence Wolfpack.

The topic was 'Direct Air Capture: Green Miracle or Greenwash'.

The experts came down heavily on the side of 'greenwash'.

Paul Bryan quickly calculated that removing 1 ppm of CO2 per year from the atmosphere would require processing 900,000 billion standard cubic feet (SCF) of air per day.

That is more than 1000 times the capacity of the entire world’s gas processing plants. However, CO2 levels are rising at a rate of 2.6 ppm per year, so 2.6 times that effort would be needed just to hold atmospheric CO2 concentration at its present level (ignoring other efforts to reduce carbon levels).

The volume of air that would need to be processed is 2.3 quadrillion SCF/d or 23 x 1015 liters per year. Alternatively, the present cost of capturing and supplying CO2 is about US$1200/ton.

Since one barrel of oil on combustion releases about half a ton of CO2, the price of crude oil should be at least US$600/bbl just to cover the cost of DAC. True, the cost will come down in time, but this illustrates the challenge.

Steven Sloane emphasized that the capex costs and energy costs are crippling for DAC. It is much cheaper to use trees or plants to absorb CO2 with the input of solar energy, with the biomaterial then used as fuel or to generate CO2 via fermentation. The process can be optimized with Regenerative Agriculture, a lofty name that really means soil carbon capture and sequestration.

DAC as Magic Beans: An Alluring Illusion

Steve Weiss compared DAC to magic beans—an attractive idea but an illusion. The dilute presence of CO2 in the air makes DAC as challenging as trying to recover the salt from a bowl of guacamole.

David Dodds discussed the moral hazard of DAC—“it means we don’t have to do anything” about climate change. He quoted an economic analysis by the model En-ROADS Climate Solutions Simulator, which states that for DAC to be successful, the price of CO2 has to be at least US$500/ton.

'...DAC gives fossil fuel companies an excuse to do nothing about reducing their carbon footprint...'

Jim Lane quoted Texas-based oil and gas firm Oxy as calculating that the capex for the construction of a DAC plant is US$1100 per ton of CO2. A back-of-the-envelope calculation then gives a total construction cost of US$42 trillion for enough such plants to bring the world to net carbon zero—equal to one year of the world's GDP!

Michele Rubino pointed out that if DAC requires a CO2 price of US$500/ton to be viable, many other technologies could well be viable at a much lower price. Perhaps not today, he says, but with a more modest development outlay than the sums being talked about for DAC.

The Regenerative Agriculture Technique

Joel Stone reverted to the highly promising regenerative agriculture technique in which CO2 is captured and then sequestered in soil. There are three times more tons of CO2 contained in the world’s soil than in the atmosphere. For every 1% increase in the CO2 content in soil, there is an increase in water absorption of 20,000 gallons per acre.

In this way, not only can CO2 be sequestered, but at the same time, soil water management is improved, leading to increased food productivity. Alternatively, crops that lead to the production of sugars and, thereafter, useful bio-products can be targeted.

Steve Weiss reminded us that a one million ton per year DAC plant involves a capex of US$1 billion. So, at a discounted cash flow over some 15 years, there is a cost of US$100/ton of CO2 just for depreciation before taking into account fixed and energy costs. Canadian clean energy company Carbon Engineering estimated the cost of carbon to make DAC viable at US$180/ton. That seems optimistic.

Steve Slome pointed out that capture and sequestration of CO2 leaves the producer with nothing in hand other than the credits obtained from the Inflation Reduction Act, plus other support systems. The danger is that support may not be continued by the government after their allotted time, depending on the whims of politicians. DAC can survive only with credits and only in the US for the moment. It is better to produce something of tangible value, like wood, which can be stored, sold, or usefully employed. DAC will not survive if new technologies emerge with lower costs, except by going cap in hand to the government. Using algae to sequester CO2 at least leads to a tangible product, though indications are that costs are even higher than those of DAC.

Paul Bryan rounded off the webinar by stating that once a project has been allocated government funds, it tends to consume all the money willy-nilly, whatever its success or failure. Which project gets chosen depends on which political winds are blowing. No lobbyist gets left behind!

No lobbyists left behind

If DAC is not the answer, what is? Jim Lane, in a later webinar, proposed that CO2 capture from the sea could be the answer. The concentration of CO2 in the sea is 100+ times higher than it is in the atmosphere. The work of capturing CO2 has already been done. It is only the cost of extraction that remains. Then, the sea will absorb CO2 from the atmosphere to restore equilibrium, and the cycle continues.

Charles Fryer, the author of this blog post, founded Tecnon OrbiChem in the 1970s and remains a special advisor to ResourceWise.

Charles Fryer, the author of this blog post, founded Tecnon OrbiChem in the 1970s and remains a special advisor to ResourceWise.

The ResourceWise group comprises renewable fuels and feedstock intelligence provider Prima Markets, as well as forestry, pulp, and paper-focused Forest2Market, Fisher International, and Wood Resources International, with a US-based glycols, methanol, and solvents-focused consultancy—Chemical Intelligence—its latest acquisition.

Subscribe to our chemicals-focused blog to stay up to date on trends in both renewable and fossil-fuel-based products.