3 min read

Optimizing Water Usage: A Key Step Towards Environmental Sustainability

Marcello Collares

:

Dec 15, 2023 12:00:00 AM

Marcello Collares

:

Dec 15, 2023 12:00:00 AM

As we look at sustainability initiatives undertaken by companies to foster a more circular economy, the emphasis is often placed on greenhouse gas emissions. While it is crucial to dedicate our efforts and attention to reducing GhG emissions, we must not overlook other vital areas, such as water usage.

Understanding the Impact of Water Usage on the Environment

Water usage has a significant impact on the environment, especially when it comes to greenhouse gas emissions and water scarcity. The pulp and paper industry, like many other sectors, can contribute to these problems. It's crucial to grasp the consequences of water usage to tackle the environmental challenges we're up against.

Excessive water usage in industrial processes can have a detrimental effect on water resources, leading to increased greenhouse gas emissions and negative impacts on our ecosystems, as well as human health and well-being. By gaining a deeper understanding of the environmental consequences of water usage, we can take proactive measures to reduce our ecological footprint and foster sustainability.

Water Usage in the Pulp and Paper Industry

The pulp and paper industry is known for its high water consumption. Water is used in various stages of the production process, including pulp preparation, papermaking, and paper recycling. This industry also relies heavily on water for cleaning, cooling, and transportation purposes.

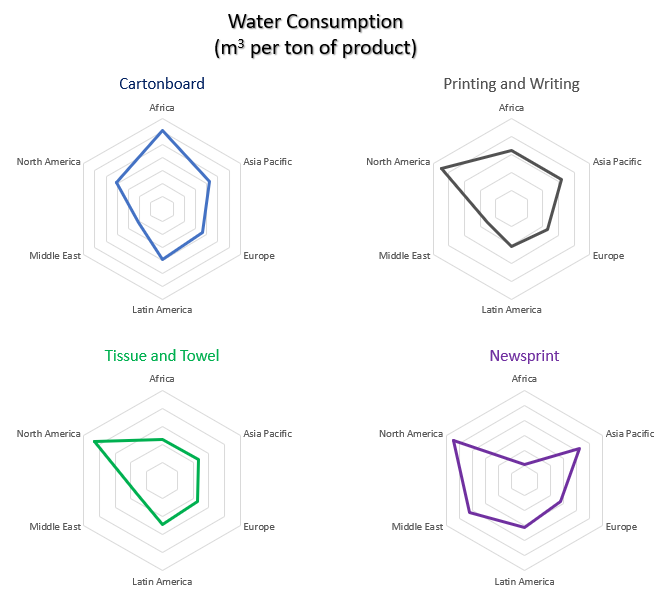

When we examine the water usage per ton of grade produced, we can see different trends in the water consumption, depending on the grade and region. Europe stands out as the region maintaining some of the lowest water usage levels for the grades listed.

Excessive water usage in the pulp and paper industry can lead to several environmental challenges. It can contribute to the pollution of water bodies, as well as the depletion of freshwater resources. Additionally, the energy required to treat and transport large amounts of water adds to the industry's carbon footprint.

When looking at the top five pulp and paper producing countries, ThinkHazard classifies hazard levels regarding water scarcity (on a scale of high, medium, low, or very low) of these countries as:

- China: High. This means that droughts are expected to occur on average every 5 years.

- United States: High. This means that droughts are expected to occur on average every 5 years.

- Brazil: Medium. This means that there is up to a 20% chance droughts will occur in the coming 10 years.

- Japan: Medium. This means that there is up to a 20% chance droughts will occur in the coming 10 years.

- India: High. This means that droughts are expected to occur on average every 5 years.

As we can see in the image below, certain countries have made significant strides in improving their water usage over the past several years, while others have not. Some have even increased their water usage.

Water Usage in the Pulp and Paper Making Process by Country

Source: FisherSolve

Countries that have not made significant improvements in their water usage need to prioritize water conservation to mitigate the environmental challenges they face. Collaborating with suppliers and customers to promote water conservation throughout the supply chain can be a valuable strategy. By sharing best practices, implementing joint water-saving initiatives, and encouraging the use of sustainable products and packaging, these countries can make significant progress in optimizing their water usage.

The pulp and paper industry must collectively prioritize water conservation and adopt sustainable practices to mitigate the negative environmental impacts associated with excessive water usage. By implementing water-efficient technologies, adopting water management practices, and collaborating with stakeholders, the industry can foster a more sustainable future.

Strategies for Optimizing Water Usage

There are several strategies that companies in the pulp and paper industry can adopt to optimize water usage and promote environmental sustainability.

- Implementation of water-efficient technologies and equipment. This includes the use of closed-loop systems, which recycle and reuse water within the production process. Companies can also invest in water-saving technologies, such as low-flow fixtures and water-efficient machinery.

- Adoption of water management practices. This involves conducting water audits to identify areas of water wastage and implementing measures to reduce consumption. Companies can also implement water monitoring systems to track and manage water usage in real time.

- Collaboration with suppliers and customers to promote water conservation throughout the supply chain. This can involve sharing best practices, implementing joint water-saving initiatives, and encouraging the use of sustainable products and packaging.

But first, you need to understand where your company falls in terms of its water usage.

Unlocking the Power of ResourceWise

FisherSolve's Water Intensity Index allows users to assess the efficiency of water conservation in mills, quantified by the volume of water used per ton of production. This invaluable tool enables comparisons and in-depth analysis within the framework of water risk for specific regions.

Having access to this type of environmental data is crucial as the global population becomes more knowledgeable about these issues, and companies' responsibility for managing water resources becomes increasingly significant. Just as the concept of 'carbon footprint' has become a standardized measure, understanding and addressing water usage will likely become an essential requirement for operating in a world that is increasingly conscious of Environmental, Social, and Governance (ESG) matters.

To gain a deeper understanding of how Fisher's Water Intensity Index and other sustainability-related benchmarking tools can empower your company with the necessary information to stay ahead in the industry, reach out to our team of experts today. We are here to provide you with invaluable insights and guidance to maintain a competitive edge.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)