Forest Products

Pricing, Mill Intelligence, Analytics, and Strategic Consulting for the Forest Products Value Chain

The forest products industry is in a constant state of change.

Supply Disruptions

Demand Changes

Price Volatility

Sustainability

Eliminate Uncertainty with Commodity Intelligence

The counterbalance to uncertainty caused by the unpredictable demand patterns, global supply chain disruptions, difficult geopolitical situations, and the Covid-19 pandemic is business intelligence.

Built from deep data and expertise, business intelligence from ResourceWise turns this complex market uncertainty into in-depth insight and strategy. We can help you leverage your strengths and opportunities and mitigate your supply chain, operational and environmental risks.

Commodity Pricing

- Stumpage Prices – North America

- Delivered Log and Wood Fiber Prices – North America

- Lumber Prices

- Recycled Fiber – North America OCC (expanding to other grades and regions)

- Global Wood Fiber, Sawlog, Lumber, Market Pulp and Pellet Pricing

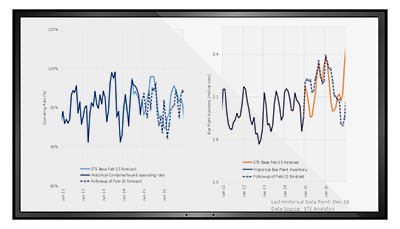

Forecasts

- Stumpage Price Forecasts – US South

- Delivered Log and Wood Fiber Forecasts

- Market Behavior Predictions (including price, price turning points and key drivers)

- Macroeconomic Indicators

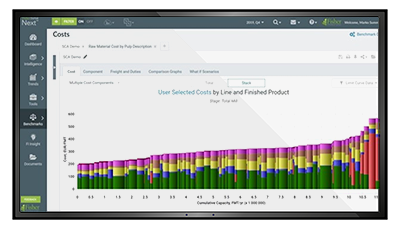

Benchmarks

- Price Benchmarks (with Cost Components)– North America Logs and Wood Fiber

- Price Benchmarks – Global Sawlog Price Index, European Sawlog Price Index (ESPI), Global Softwood Fiber Index (SFPI), and Global Hardwood Fiber Index (HFPI)

- Pulp and Paper Benchmarks – Mill Cost, Environmental Flows (Carbon, Water, and Energy), End-product Destination, and Asset Quality and Viability Indexes

- Mill-to-Mill Benchmarks for Sawmills and Pulp and Paper Mills

- Recycled Fiber

- Cost Curves

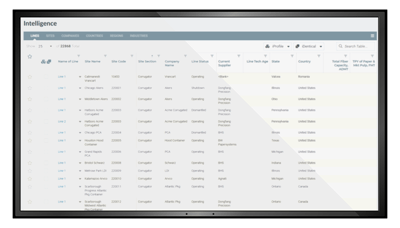

Pulp, Paper and Corrugator CRM

- Ownership and Contact Information (every pulp and paper company in the world producing 50+ tpd)

- Asset Data (process equipment and control systems and mill configurations)

News and Insights

- Pulp and Paper Industry News

- Global Forest Supply Chain Commentary

Trade Data and Flows

- Import and Export Data and Visualizations -- Hardwood Chips, Softwood Chips, Market Pulp and Pellets

Forest Product Industry Commodity Intelligence Platforms

ResourceWise's powerful, intuitive business intelligence platforms leverage our deep historical databases covering prices and other market trends. Our expertise stems from the experience of our legacy companies in providing the most accurate market data available.

Our goal is to supply the data and advice you need to lead your organization directly to the most effective action.

Forestat Global complements our existing platforms while providing you with a comprehensive, enhanced view of the market, with no data contribution required.

FisherSolve is a robust platform for pulp and paper professionals, providing data and information on the operations of every pulp and paper mill in the world.

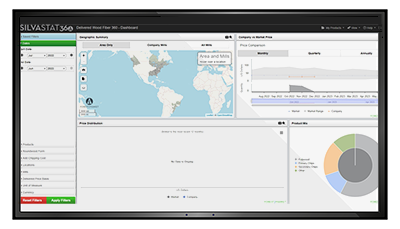

SilvaStat360 is a flexible, intuitive business intelligence platform for professionals in the forest products supply chain, providing pricing and mill-to-mill benchmarking.

Global Forest Supply Chain and Insights

WoodMarket Prices is an online platform covering prices, trade data, and commentary about market trends in global forest products markets.

- Timberland owners, managers and investors

- Lumber and other wood products manufacturers

- Pulp, paper, and packaging producers and suppliers

- Industrial wood pellet, biofuels, and biochemicals producers, buyers, and investors

- Corrugated packaging producers and suppliers

- Recycled paper generators, collectors, and buyers

- Consumer packaged goods producers and retailers

We specialize in leveraged consulting, helping clients quickly understand their competitive positions and develop asset optimization strategies before making significant investments.

Our experts provide insights and solutions to address our client's challenges with speed and effectiveness.

ResourceWise excels at helping customers optimize their businesses for environmental and financial success.

FAQs

-

What is the forest value chain?

A value chain is a series of activities needed to bring a product from raw material and consumer use to disposal.

A forest product value chain focuses on activities that generate value for both timber and non-timber forest products. These move from processing and production to consumer delivery and disposal. Specific activities include harvesting, cleaning, transport, design, processing, production, transformation, packaging, marketing, distribution, and support services. All these activities add value to the product as they move across the chain.

To participate in forest product value chain industries, businesses need to compete on a global scale. This means navigating an ever-changing market and analyzing data across all aspects of the value chain. Additionally, there’s increasing pressure to source sustainable alternative sources to move toward reducing carbon emissions throughout each step in the process. This can add further variables and complicate the process.

-

What is the Sustainable Forestry Initiative?

The Sustainable Forestry Initiative (SFI) is one of the world’s largest sustainability organizations, operating in the U.S. and Canada. It works across four pillars: standards, conservation, community, and education. It is the largest single forest certification standard by area and covers key values such as the protection of biodiversity, species at risk and wildlife habitat, sustainable harvest levels, protection of water quality and prompt regeneration.

Practicing sustainable forestry ensures that wood and paper products can continue to be provided while participants conduct the best management practices in supplying the needed fiber. This program provides a framework for foresters, landowners, loggers and wood and paper producers for producing sustainable products. It also protects sustainable forest value chains in multiple ways.

The SFI is supported by a wide range of participants, including forest products companies, landowners, forestry associations, forestry consultants, product companies, universities, and loggers. ResourceWise’s platforms can help a wide range of participants by providing accurate, up-to-date analytics. This helps to empower change and sustainable practices around the world.

-

Are pulp and paper renewable?

Yes, pulp and paper are forest products, which means they are renewable resources. The pulp and paper industry has a long history of environmental stewardship and is committed to sustainable practices.

Some ways the pulp and paper industry is working to protect the environment:

-

Harvesting from sustainably managed forests to produce paper that minimizes damage to the environment.

-

Implementing water conservation measures such as using recycled water, implementing water conservation measures, and reducing water pollution.

-

Using renewable energy sources like biomass to power operations and reduce greenhouse gas emissions.

Aside from implementing these measures, the industry actively encourages the use of recycled pulp and paper fibers. These materials can be recycled multiple times without losing quality. Recycling helps to reduce the overall demand for new paper and conserves many other resources.

-

-

What is a forest management plan?

Forest management plans are a list of goals and outcomes for forests or wooded areas focusing on specific environmental, economic, social, and cultural objectives. These plans can be scaled from local to national scales.

Forest management plans preserve the existence and functionality of forest resources, manage costs, reduce risks, and plan future harvesting activities.

Steps in creating an effective plan include completing an initial land assessment, taking forest resource inventory, setting goals, calculating sustainable yields, getting approval, and revising the plan regularly based on current issues impacting both the environment and the market.

Using accurate analytics tools to inform and guide your planning is essential. These will empower more accurate decision-making about your forest to ensure ongoing success in a constantly changing market.

-

How are harvested trees used?

The harvest and subsequent regeneration of trees is a serious business for the forest industry. As a result, any claim that whole trees are used for anything less than their full potential is wildly frustrating. Landowners manage forests to maximize tree growth, and subsequently, return on investment. Forest products companies use the trees they purchase from landowners to the fullest extent possible. When trees reach a diameter large enough to produce high-value wood products, a final harvest takes place. Three raw materials come out of a harvest: sawtimber, pulpwood, and harvest slash.

Trees with straight trunks are needed to produce sawtimber, which is the portion of a mature tree that runs from the stump through the largest diameter used to produce valuable lumber and plywood.

Trees with bends in their trunks as well as the portions of the trees that are too small in diameter to make lumber are pulpwood, and they are used to produce pulp, paper, plywood, OSB and wood pellets.

The remainder of the mature tree (top, limbs, and pine needles) is often called harvest slash. Mills use harvest slash to generate heat and electricity to run their operations. A portion of harvest slash is also left on the forest floor to prevent erosion, nourish the soil, and provide wildlife habitat.

-

What are sustainable aviation fuels?

SAF is a broad-based segment of biofuels used to power aircraft that has similar properties to conventional jet fuel but with a smaller carbon footprint. Depending on the feedstock and technologies used to produce it, SAF can reduce lifecycle greenhouse gas (GHG) emissions dramatically compared to conventional jet fuel.

SAF can be produced from various sources, including woody biomass. An estimated 1 billion dry tons of biomass can be collected sustainably each year in the United States; enough to produce 50–60 billion gallons of low-carbon biofuels. These resources include corn grain, algae, other fats, oils, and greases, agricultural residues, as well as forestry residues, and wood mill waste.

Originally, both agriculture and forest biomass were expected to contribute to creating biofuels, but in practice, the renewable fuel standard (RFS) and RFS-2 built a framework that was designed to disincentivize the removal of forest resources from public lands and ecologically sensitive areas. The US produces corn on about 90 million acres/per year, which generates 3-4 tons/acre of corn stover (waste).

Forest biomass, however, can be harvested from roughly 300 million acres with 1-2 tons/acre of residual material. In other words, there are no major EPA restrictions on stover, while there are major restrictions on wood biomass.

Despite the hurdles, wood-based SAF investments are flowing into the US South due to the region's deep inventories of pine forest resources, which are overwhelmingly managed by private timber owners who manage these resources as economic assets. This makes the South the lowest-cost forest economy in the US, and one of the most competitive in the world.

-

What is forest thinning and why is it important?

Properly managed, working forests have both economic and ecological benefits. Regular thinning provides an improved environment for maximizing a site’s growth potential, which results in larger, healthier trees and more valuable timber.

One of the benefits of regular thinning is that it allows the continued growth of the healthiest preferred species within a timber stand while removing the suppressed, diseased, and low-vigor trees that will impede the growth of the entire stand. Many of the low-vigor trees in such stands continue to grow at a reduced rate until competition claims them or they are removed via thinning.

Thinning is not only good for forests and landowners, but it also reduces the more severe effects of wildfires. Experts in forestry and wildfire ecology have almost unanimous agreement that fuels reduction is important for forests to thrive and reduces the danger and risks of severe wildfires.

Critics of forest thinning argue that forests should remain untouched, as nature intended. From a philosophical standpoint, we agree that there is value in an untouched old-growth forest. However, due to climate change and the associated increased wildfire risks, we need to intervene to mitigate the risks caused by human activity. One of the best ways to mitigate the risk is through routine, targeted forest thinning.

-

Which is better: single-use or reusable packaging?

According to Two Sides – Europe, the answer depends on the context of the given product or value chain. The short answer is that both are important to deliver optimum efficiency of resources.

RPC’s (Returnable Plastic Containers) are a good example of reusable packaging. They are great for moving goods from a local distribution hub to a retail store, provided there is a closed-loop network in place. Collapsible RPC’s are a great innovation that has transformed how goods are efficiently moved over short distances.

Longer distances and more complex, unpredictable supply chains add challenges. RPC’s need to be used at least 50 times, if not more, to be effective. Any example that can’t deliver this ROI, means that a single-use, recyclable box, carton, or tray will probably be a more viable choice, provided it is produced from regenerative, low-carbon, and managed material sources certified by FSC, PEFC, etc.

Single-use containers are generally also more space-efficient because they can be adapted and optimized to reduce waste in transport, storage, picking, packing, and handling. They also provide more flexibility when it comes to branding and communicating safety information – an important part of merchandizing consumer products.

While there are many other great examples of single-use and reusable packaging, both play an essential role in protecting, preserving, transporting, storing, dispensing, identifying, and displaying consumer products. Selecting the best option should be decided on a case-by-case basis, considering all variables, and reviewing regularly. Selecting suitable materials that are abundant, regenerative, and non-polluting is essential for any packaging design decision as it reduces negative social, environmental, and commercial impacts.

-

Folding Box Board (FBB) vs. Solid Bleached Sulfate (SBS).

The main difference between FBB and SBS is that FBB is always multi-ply and utilizes a combination of chemical and some form of mechanical pulp (MP) or thermomechanical pulp (TMP). Whereas SBS can be either single or multi-ply board but is always comprised of 100% chemical pulp.

What is FBB? FBB is layered with mechanical pulp that is sandwiched between outer layers of chemical pulp with an optional coating. Being a virgin fiber paperboard with consistent purity for product safety, the combination of inner layers of mechanical pulp and outer layers of chemical pulp creates a low-density, bulky board with excellent folding and printing characteristics. Major end uses of FBB include:

- Frozen and chilled packaged foods

- Liquid packaging board

- Take-out boxes

- Health and beauty products

- Electronic packaging

- Confectionary

The leading regions of FBB include Europe, South America, and Asia. It is also India’s primary packaging substrate used by businesses.

What is SBS? SBS is purely constructed of bleached chemical pulp with a coated top side that creates excellent printing characteristics with moderate strength. These boxes are popular with most industries and used to package:

- Pharmaceutical products

- Food

- Cosmetics

- Tobacco

- Frozen food

North America is the leading region for SBS production, and over half of the world’s supply of SBS comes from North America and is used for packaging retail products.

Explore Our Latest Forest Products Industry Insights

1 min read

Nordic Forest Products Sector Under Pressure from High Wood Costs and European Environmental Regulations

Jun 11, 2025 by Audrey Dixon

3 min read

Unlocking the Power of FIA Data with ResourceWise’s Timber Supply Analysis 360 and Carbon 360

Jun 9, 2025 by ResourceWise

2 min read

Nordic Forest Products Industry Round-Up: Spring 2025 Insights

Jun 2, 2025 by Kai Merivuori