Over the past few weeks, I have had the opportunity to speak with a dozen or more loggers across the Northeast, and I am worried about what I hear. Almost universally, loggers express concerns about their economic health and wonder what their future will bring.

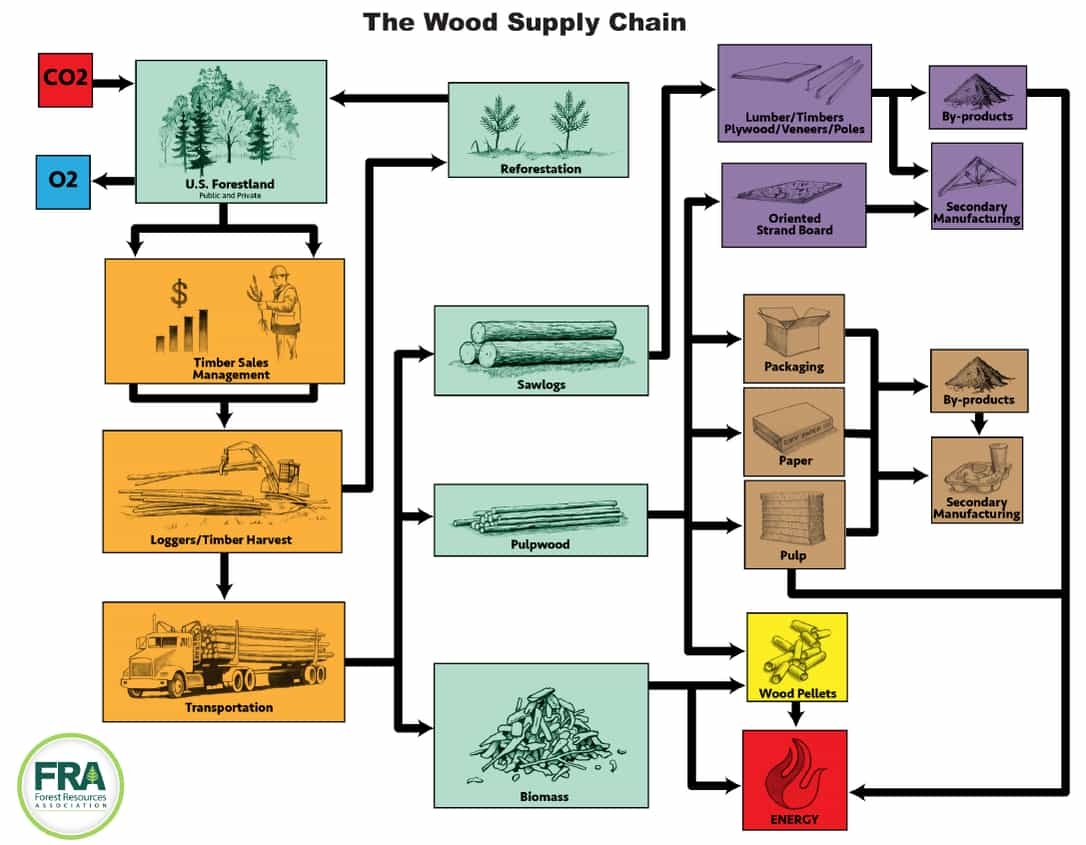

As is obvious to anyone in the forest industry, loggers and truckers are the supply chain links that connect the woods to the mill. In FRA’s supply chain schematic, there are a lot of arrows connecting lots of products, but for anything to get from the woods to the consumer, the industry relies on loggers and truckers. If loggers aren’t healthy, it’s hard for any other sector to be healthy for very long.

What’s behind this? There are probably some reasons specific to the Northeast, such as particular market dynamics or weather, but much of what I heard impacts the logging sector nationally. Trucking challenges, labor shortages, and inflation were mentioned, and combined are taking a serious toll on the people who harvest and move wood.

Let’s start with inflation. A new report from the Professional Logging Contractors of Maine says that inflation is hitting loggers hard. Loggers are paying 24% more for key supplies than in 2020. I haven’t seen the methodology, so I won’t vouch for the exact number, but…this seems right. As noted in a MaineBiz article about logger inflation:

“Price increases ranged from 17% more for equipment and truck insurance to a 30% premium for lubricants and film. The inflation far exceeds the average 8.4% rise in costs for American consumers over the same period.”

Many of the loggers I spoke with expressed this in less numeric terms. Basic parts aren’t available from local suppliers, and something as simple as a broken plexiglass windshield can idle a machine for weeks while waiting on a part to arrive. Diesel Exhaust Fluid is hard to find and costs more. Insurance is up. Diesel is $4.15 a gallon, up from a little under $3.00 a gallon a year ago. None of this makes harvesting and trucking wood any cheaper.

For trucking, one supplier told me that he has four drivers working for him, and the youngest is 70 years old. Yes, you read that correctly. While this may be an outlier, looking at our trucking workforce shows that it needs an infusion of new drivers. Currently, there aren’t enough people to drive from the woods to the mill, and the demographics don’t suggest this will get better on its own.

On the labor side, loggers can’t find enough people to work in the woods. Of course, this isn’t specific to loggers. I hear this from mills, I hear this from forestry firms, and I hear it from my grocery store. There are likely multiple reasons for this labor shortage, but it is undeniable that there aren’t enough people in or entering the workforce and that this problem is heightened in rural areas.

As with most complex problems, there likely aren’t easy answers here. It’s unlikely that there is a simple solution and likely that we’ll need multiple strategies deployed in a variety of ways to make certain the logging workforce remains healthy. What is clear is that the entire forest products industry relies on loggers in order to operate, and it’s in everyone’s interest to make sure that wood can get from the woods to the mill.

Eric Kingsley is Vice President of Innovative Natural Resource Solutions, LLC. With a diverse professional background, Mr. Kingsley has been the Executive Director for a 1500 member forestry trade association, has represented organizations in both lobbying, legislative and development capacities, and has supported state and federal agencies with disaster relief funding for the forest industry.