2 min read

Planning Your Next Mill With SilvaStat360’s New Virtual Mill Tool

Forest2Market

:

Jun 2, 2022 12:00:00 AM

The southern United States is home to some of the world’s most productive forests and as such, it is a popular destination to relocate or site new wood-consuming facilities. The forest products industry in the US South is vibrant, but feedstock availability for a mill depends on a number of factors ranging from weather patterns and seasonality to the economic cycles of those operating within the region. As new facilities continue to come online, competitive factors cannot be overlooked.

Making the Right Moves for Success

Proper site selection of a new wood-consuming manufacturing facility is imperative for its long-term success. Prior to siting a new facility, or even deciding whether to repurpose an existing one, due diligence requires that the project developer seek verification that adequate raw material can be procured from the supply region for the life of a project. The unique factors that are specific to each supply basin must be analyzed before formulating a strategic plan for procuring wood.

Accounting for current and future forest inventory and consumption, as well as understanding how ownership profiles impact the supply chain, will improve profitability and drive success. An accurate picture of current supply can be constructed by looking at different procurement zones within individual wood basins and answering some key questions:

- What is the available supply for the target forest product(s)?

- What is the current demand for these products?

- What competitive facilities exist in the procurement zone?

- What are the current and historical delivered prices for these products?

The cost of wood depends on both demand and the supply of wood raw materials available to meet that demand. It is also important to remember that stumpage prices may spike when new demand enters the market, which puts pressure on current forest resources and logging capacity. As the forest products industry in US South continues to grow, new project success and profitability depend on a keen understanding of the dynamics that drive these demand scenarios.

SilvaStat360 Virtual Mill

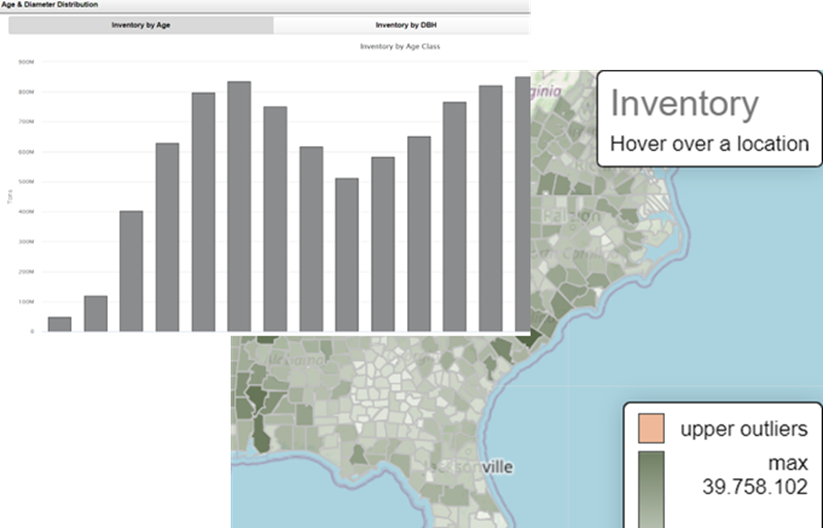

Since rolling out the SilvaStat360 interactive digital platform in 2017, Forest2Market has continued to develop a series of innovative and analytical solutions for participants in the global forest value chain. Our newest interactive visualization includes a Virtual Mill tool for consumers of both wood fiber (pulpwood and chips) and logs (sawtimber).

Understanding the intricacies that underpin a hypothetical mill’s location and delivered wood price, as well as its position, advantages, and disadvantages vs. the market is imperative for the mill’s success and profitability, and it helps shape decision-making for the future. For subscribers to Forest2Market’s Delivered Price Benchmark service, the new Virtual Mill tool provides a full-spectrum view of the criteria that will impact the performance of a theoretical new facility, and it incorporates current delivered prices based on the highest-quality transactional data in the forest products industry.

In the accompanying case study, we used Virtual Mill to study a 75-mile procurement zone radius around a hypothetical sawmill in which we analyzed the types of competitors and other wood consuming facilities that exist in the basin, as well as delivered prices for pine sawtimber. We also utilized some of the other tools available in SilvaStat360 to look at available timber supply and average precipitation in the procurement zone, as well as macroeconomic drivers that impact finished lumber prices.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)