2 min read

How Fisher International Predicted the Recyclability of Fiber-Based Packaging

.png) Tedd Powers

:

Mar 30, 2022 12:00:00 AM

Tedd Powers

:

Mar 30, 2022 12:00:00 AM

In 2017, Fisher International presented at TAPPI’s Papercon on the state of recycled fibers. At the time, our modeling suggested that the “seven turns” theory that was commonly accepted within the industry was incorrect. Now, with the benefit of time and testing methodologies, a new study has also reached the same conclusion: Fiber-based packaging material can, in fact, be recycled more than 25 times without sacrificing product integrity.

To provide a little more background, recycled fiber was a prevalent industry topic of discussion in 2017 as the cost to use OCC increased dramatically at the time. As a result, many producers, customers, analysts and industry watchers raised concerns about the future supply of recycled fibers – specifically OCC. In Fisher’s presentation for TAPPI, we challenged some commonly held beliefs within the industry about recycled fibers.

Firstly, there was a general misconception at the time that the world was about to run out of OCC due to a couple of commonly held ideas: 1) recovery rates were approaching their practical limits, and 2) fiber was only able to be recycled roughly seven times without sacrificing integrity. This was ultimately deemed the “seven turns” concept – a persuasive narrative that we would run out of recycled fiber and informed the dominant industry thinking since the early 2000s.

However, after digging deeper into some interviews and building our own data-based model, we learned that actual fiber loss is significantly less than what is implied by reported yields.

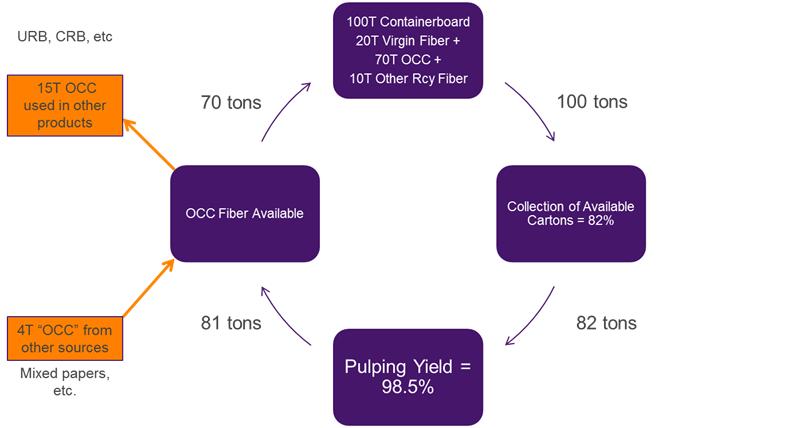

Interviewees consistently indicated that the vast majority of the “loss” in the OCC plant was actually non-paper items such as glass, plastic, rocks, tape, glue, and non-repulpable paper. In fact, most interviewees in North America and Europe reported actual fiber losses in the low single digits. Fisher then demonstrated that the robust model we built calculated the likely fiber loss based on a number of factors. According to our model, we determined that a fiber yield of 98.5% is required to balance the system. So, under the conditions that there is only a 1.5% fiber loss each time we recycle it, actual turns can feasibly be more than 50.

Why Does This Matter?

Recently, a new university study conducted by Graz University of Technology in Austria corroborated our findings and stated that fiber-based packaging material can be recycled more than 25 times with little to no loss of integrity – exactly what we’ve been saying for almost five years. This has been, and continues to be, a critical topic because it’s an important variable in thinking about the global balance of recycled and virgin fiber and consequently, the amount of virgin fiber that is needed.

As we’ve discussed before, using Big Data and reliable analytics when it comes to decision-making that challenges dominant industry thinking is crucial – and studies like this further illustrate that fact. In our consulting experience, we often assist companies who have underwritten their strategies based on premises that may be out of date or incomplete assessments of their markets.

Whether you are looking for guidance on specific projects or simply wish to redefine your company’s strategic approach, Fisher International helps you uncover the critical insights that are necessary to drive data-informed decision-making. Our business intelligence system FisherSolve Next contains highly detailed and complete information on every pulp and paper mill the world with data on assets, production, long-term viability, carbon footprint and more, which Fisher is able to leverage to help clients forge a successful path forward. As demonstrated above, we have the data and business intelligence to elevate your strategic thinking and drive practical competitive advantage.

![[Video] Molecules to Markets Episode 1: Chemical Markets Begin 2026 in a Supply-Driven, Margin-Sensitive Environment](https://www.resourcewise.com/hubfs/images-and-graphics/blog/chemicals/2026/weekly-video-series-molecules-to-markets/CHEM-Weekly-Video-Series-Molecules-to-Markets-Episode-1.png)