4 min read

Biobased Phthalic Anhydride: Can this Key Feedstock be Green?

Jane Denny

:

Feb 13, 2023 12:00:00 AM

Jane Denny

:

Feb 13, 2023 12:00:00 AM

Phthalic anhydride is a key chemical intermediate in applications from phthalate plasticisers to polyesters. Many types of polyesters can be made via reaction with glycols, from alkyd resins and unsaturated polyester resins to polyols for polyurethanes (PU).

Tecnon OrbiChem’s data platform OrbiChem360 calculates global production capacity at 6.4 million metric tons in 2022 – over half in China or Northeast Asia, and all coming from petrochemical-based sources.

Since there are currently no commercial biobased phthalic anhydride (PA) products available, a non-fossil aromatic could prove a gamechanger.

Missing link

Renewable chemistry startup Relement claims to have uncovered the missing link needed to create a largely sustainable alkyd/polyester coatings.

Noting that the aromatic is the key ingredient needed to make coatings sustainable, Relement chemists set out to replace that petrochemical element with a bio-derived alternative that gives coatings the gloss, scratch resistance and UV-stability of traditionally-made coatings.

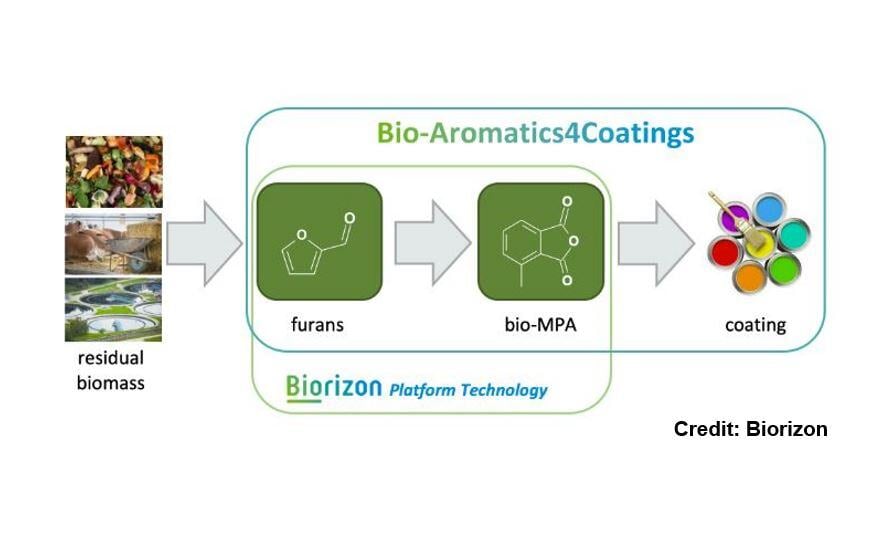

Not only does Relement’s bio-MPA (3-methyl phthalic anhydride) replace the fossil ingredient PA in coatings, the Dutch startup says its product increases coatings hardness – making it potentially longer-lasting than its petrochemical counterpart. After demonstrating the product’s viability at lab level, Relement enlisted the R&D arm of science company Solvay to scale-up its proprietary product in April 2022.

In addition to a coatings application, bio-MPA is suitable for specialty polymers, adhesives and resins. Membership-based research consortium Biorizon – the TNO program from which Relement was spun out in 2020 – describes 3-MPA as a biobased near-drop-in replacement for petrochemical PA.

'It has been shown to have beneficial effects – or comparable effects – when compared to PA in end-user products such as coatings, pigments and PU. Due to lower viscosity, the film demonstrates improved spreadability. It also yellows less than traditional materials,' according to Relement. Meanwhile, claims attributed to the firm's external sources say bio-MPA cuts CO2 emissions – 3.1kg CO2 eq/kg bio-MPA compared to the fossil-based equivalent.

Lab work was carried out at Biorizon’s facility in the Netherlands-based Green Chemistry Campus after Relement was awarded a React-EU grant to lead the Bright Coatings consortium and prove its technology by delivering 100 kg of bio-aromatic MPA via Diels-Alder chemistry. As part of the collaboration, the coating will be demonstrated on an electric wheel loader vehicle.

Feedstock suppliers included Lenzing – the Austrian wood-based chemicals company; forestry and agricultural residues biotech company Vertoro and beet-based sustainable chemicals producer Cosun – both of which are Netherlands-based.

Renewable biomass

The starting material for Relement’s biobased aromatic MPA is 2-methylfuran (2MF). It can be produced from furfural, a material derived from biomass that has been used as a renewable feedstock in chemical production processes for centuries. Hemicellulose – the part of a plant that binds its structural elements together – is a non-food feedstock forming 20-30% of biomass such as seeds, husks, straws, leaves and wood. Also known as xylan, it is hydrolysed chemically or enzymatically to produce the furfural feedstock for bio MPA.

As one of Earth’s richest polysaccharide sources – alongside starch, glycogen – hemicellulose is attracting increasing attention due to its biodegradability, renewability abundance. While cellulose is an un-branched long chain polymeric molecule comprising the glucose monomers of plant cell walls, hemicelluloses are branched and shorter in length than cellulose.

For the bio-MPA to be fully renewable, the maleic anhydride used to make it should be made by a bio process – which is not currently commercialised

Academic scientists have been keenly focused on hemicelluloses in sustainable food packaging applications [1] and Relement's use of a derivative of hemicellulose – namely 2-methylfuran – for conversion into a PA is interesting. What is not mentioned is that the 2-methylfuran has to be reacted with maleic anhydride (MA) to make this product. For the bio-MPA to be fully renewable, the MA used to make it should be made by a bio process – which is not currently commercialised.

Tecnon OrbiChem's biomaterials expert Doris de Guzman proffers the use of biogas for feedstock to obtain n-butane as one non-fossil-based solution. 'BASF has been using biogas in some of its intermediates chemical processes in Germany, but in this instance it requires several processing steps that make it an expensive route.

''Technologies from Relement and Dutch chemistry tech developer BioBTX can yield biomass-derived benzene, making fully bio-based MPA from bio-benzene possible. However, making MA from furfural remains the most plausible route to bio-MA', de Guzman adds.

Market reaction

Tecnon OrbiChem’s PA expert Ben Edmunds says the innovation is still too early in development to have reached his contacts’ radars. ‘Though none of my contacts had heard of this, many were interested to know more,’ Edmunds adds.

‘Whether the market would be receptive to a product like this will be very much dependent on price, region and performance/application. Compared to well-established petrochemical-based equivalents, biobased products are often more expensive.

‘The US market can be much less likely to pay a premium just for the biobased label compared to the European market participants, who are more receptive even if performance is only comparable – as opposed to an improvement on traditional feedstocks.

‘That said,’ Edmunds adds, ‘If the process is scaled up cost-effectively, providing a match for the petrochemical-based prices, then both regions would likely be receptive.'

'If it outperforms traditional PA for particular end-use industries, then those downstream markets

will likely be willing to pay a premium'

Ben Edmunds, Tecnon OrbiChem consultant, orthoxylene, phthalic anhydride and synthetic fibres

Beneficial effects

Producing chemicals such as PA and feedstock for performance plastics and packaging solutions from renewable biomass is crucial in the drive to net zero. Brands – spurred by public anxiety about CO2 emissions that fossil fuels derivatives create – are increasingly drawn to sustainable development and Environmental, Social and Governance (ESG) philosophies. A biobased PA would be a key step to making the chemical industry more sustainable.

In addition, as Biorizon says, the replacement has been shown to have 'beneficial effects – or comparable effects – when compared to PA in end-user products’.

‘If the former is correct,’ says Edmunds, ‘and it is indeed capable of outperforming traditional PA for particular end-use industries, then those downstream markets will likely be willing to pay a premium over traditional PA for that improved performance'.

'This would provide Relement a double selling point – a product that is biobased and offers enhanced performance. And that goes for the US market too,' he adds.

References

- Nechita, P. et al. Sustainability.2021 DOI: 3390/su132413504

- Zhao, Y et al. Polymers2020 DOI: 3390/polym12081775